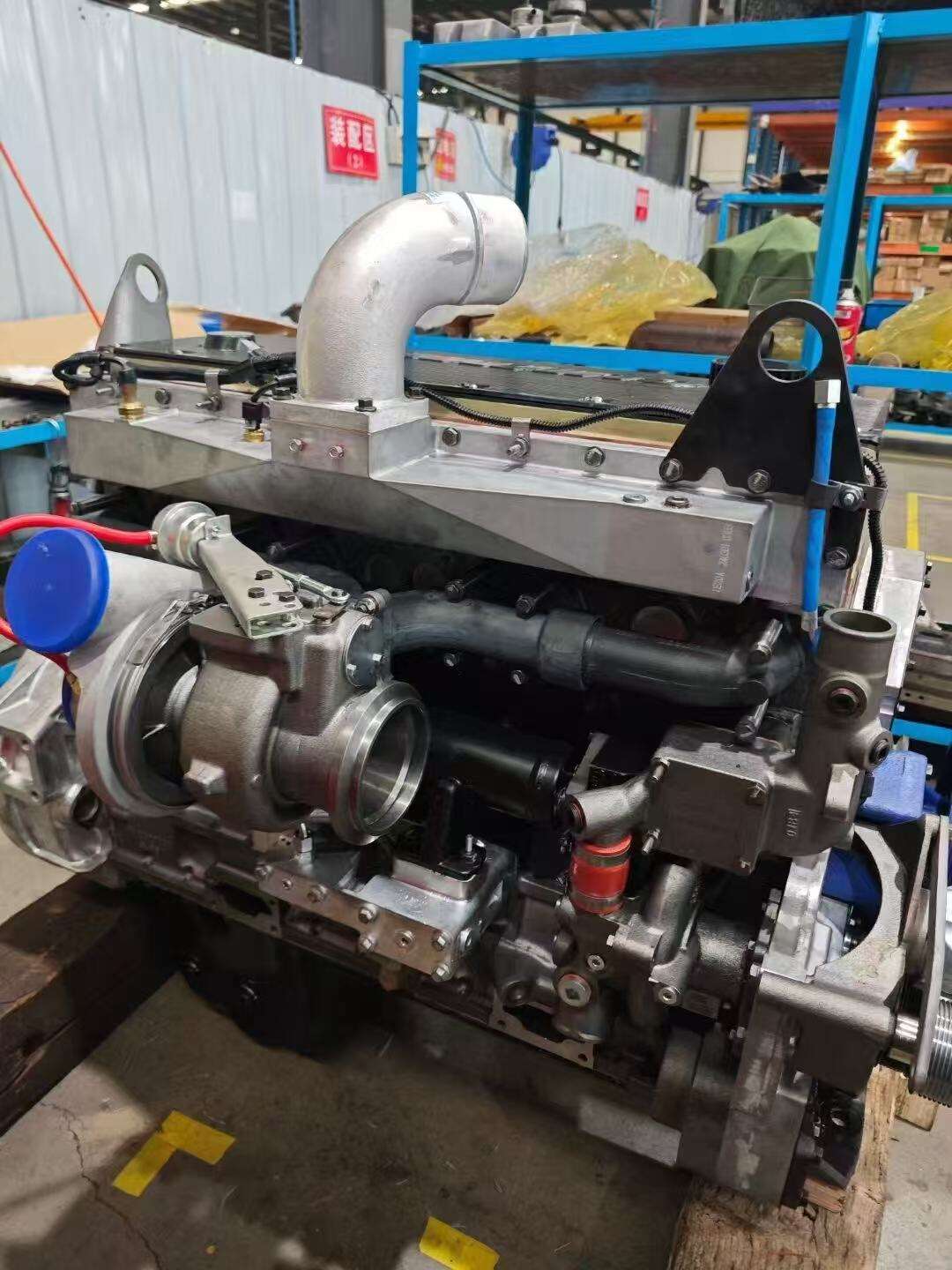

remanufactured engine in stock

A remanufactured engine in stock represents a meticulously rebuilt powerplant that delivers like-new performance while offering significant cost savings. These engines undergo a comprehensive restoration process where skilled technicians completely disassemble the original unit, thoroughly clean all components, and replace worn parts with new ones meeting OEM specifications. Each engine receives updated components including new pistons, rings, bearings, timing chains, and gaskets. The restoration process incorporates modern manufacturing techniques and quality control measures to ensure reliability and longevity. These engines are precision-machined to exact tolerances and undergo rigorous testing procedures before being certified for sale. Available for immediate delivery, these units come with warranty protection and are compatible with a wide range of vehicle makes and models. The remanufacturing process addresses common wear points and known issues of original designs, often resulting in improved performance compared to the original engine. Advanced diagnostic equipment validates proper operation across all operating parameters including compression, oil pressure, and timing. This thorough approach results in a dependable power unit that provides reliable service while reducing environmental impact through the reuse of core components.