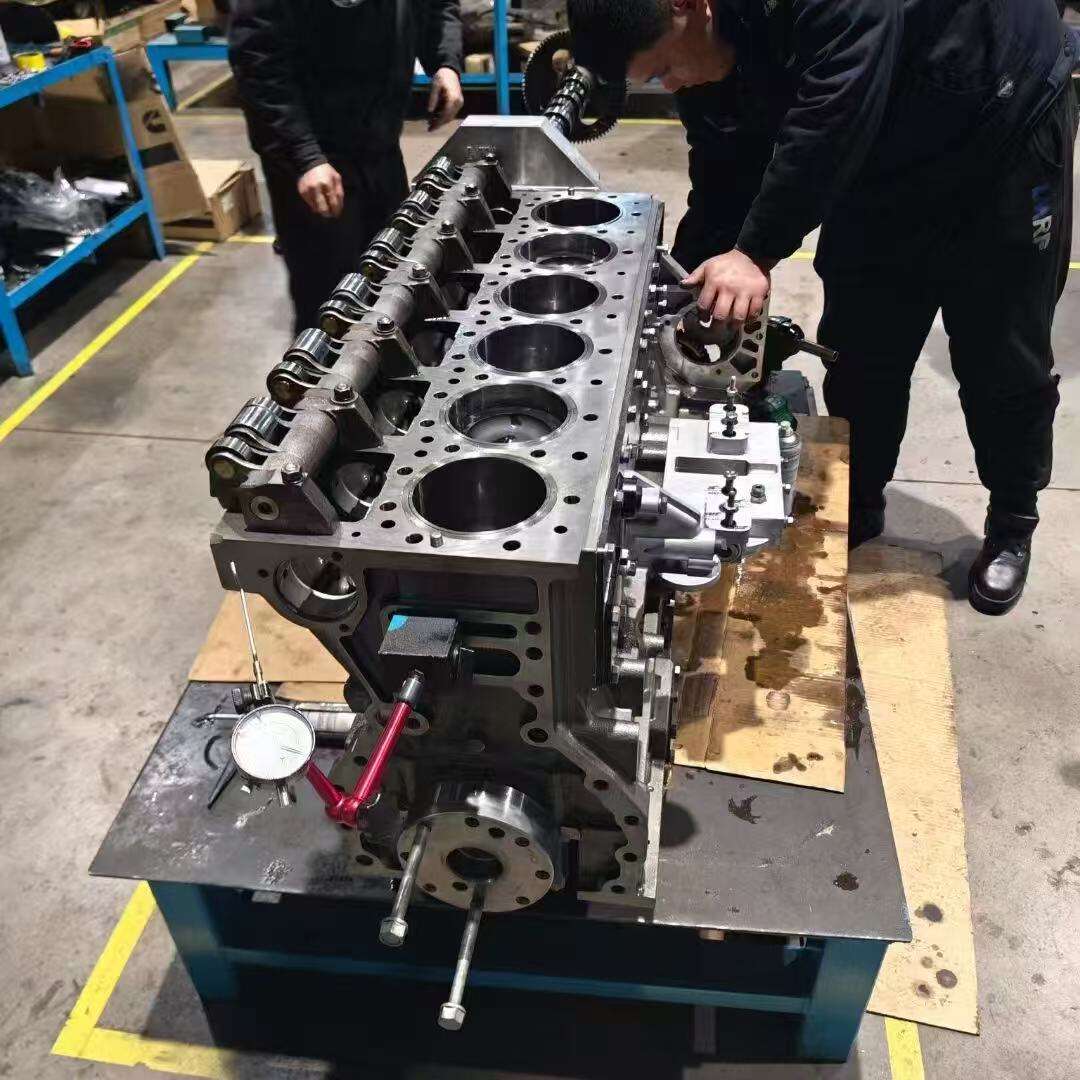

china remanufactured engine

China remanufactured engines represent a sustainable and cost-effective solution in the automotive industry, offering thoroughly restored power units that meet or exceed original equipment manufacturer specifications. These engines undergo a comprehensive rebuilding process that includes complete disassembly, thorough cleaning, precise inspection, and restoration using state-of-the-art equipment and techniques. Each component is carefully examined, with worn parts replaced using high-quality materials and updated technology where applicable. The remanufacturing process incorporates modern engineering improvements, addressing known issues in original designs while maintaining compatibility with existing vehicle systems. These engines feature updated wear components, restored bearing surfaces, and newly machined critical parts, ensuring optimal performance and reliability. The process typically includes advanced testing procedures, including computerized performance testing and quality control measures, to verify that each engine meets strict specifications for power output, efficiency, and emissions standards. These remanufactured engines are particularly valuable for fleet operations, private vehicle owners, and industrial applications where reliability and cost-effectiveness are paramount considerations.