china remanufactured engine manufacturers

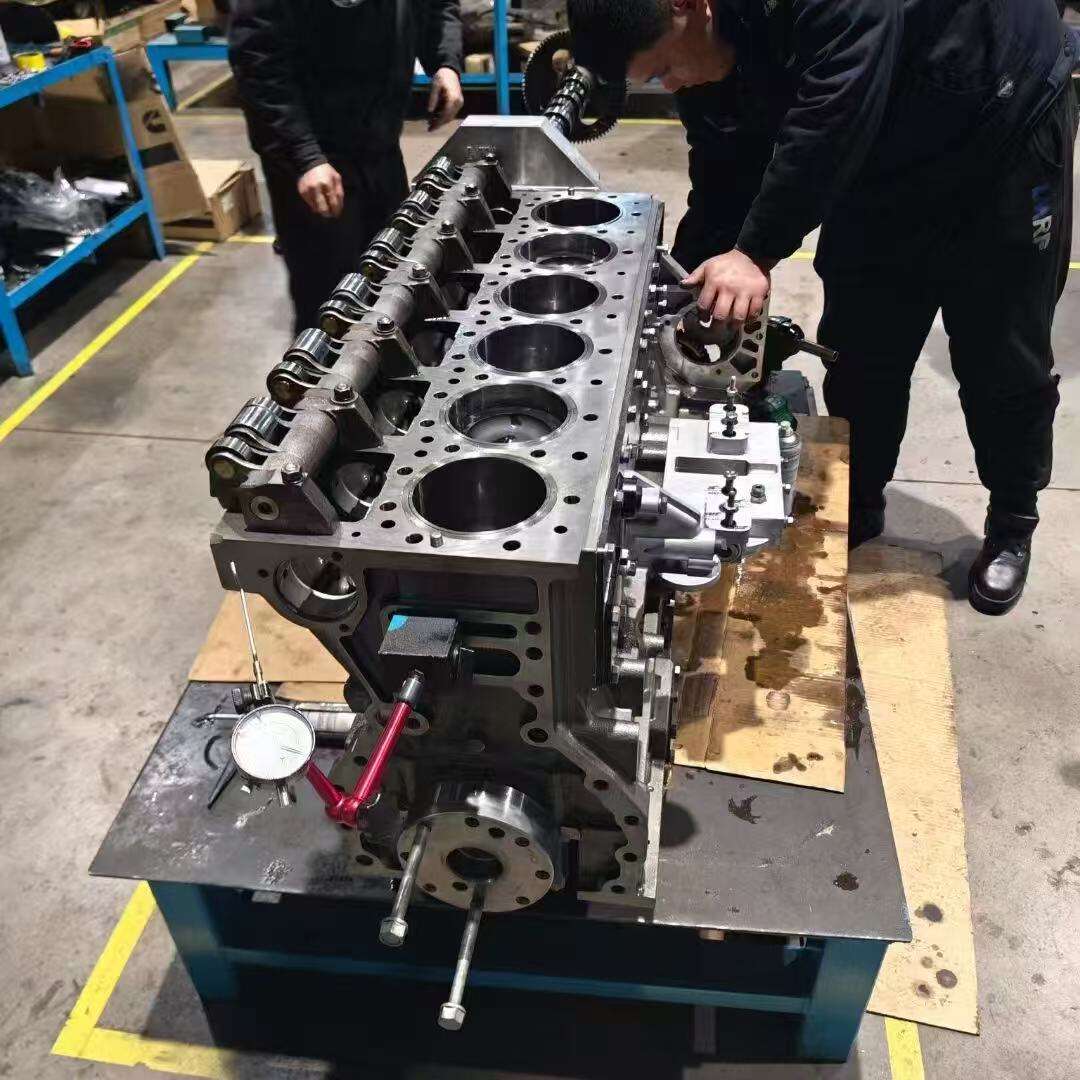

China remanufactured engine manufacturers have established themselves as leading providers in the global automotive aftermarket industry, specializing in the restoration and rebuilding of used engines to meet or exceed original equipment manufacturer (OEM) specifications. These manufacturers employ advanced technological processes and quality control measures to disassemble, clean, inspect, and rebuild engines using a combination of new and reconditioned parts. Their facilities are equipped with state-of-the-art machinery and testing equipment to ensure each remanufactured engine meets stringent performance standards. The manufacturing process involves thorough inspection of core components, replacement of worn parts, precise machining operations, and comprehensive testing procedures. These manufacturers typically offer a wide range of engine types, including gasoline, diesel, and hybrid variants, catering to various vehicle makes and models. Their products serve multiple sectors, from individual vehicle owners to fleet operators, providing cost-effective alternatives to new engine purchases while maintaining high quality and reliability standards.