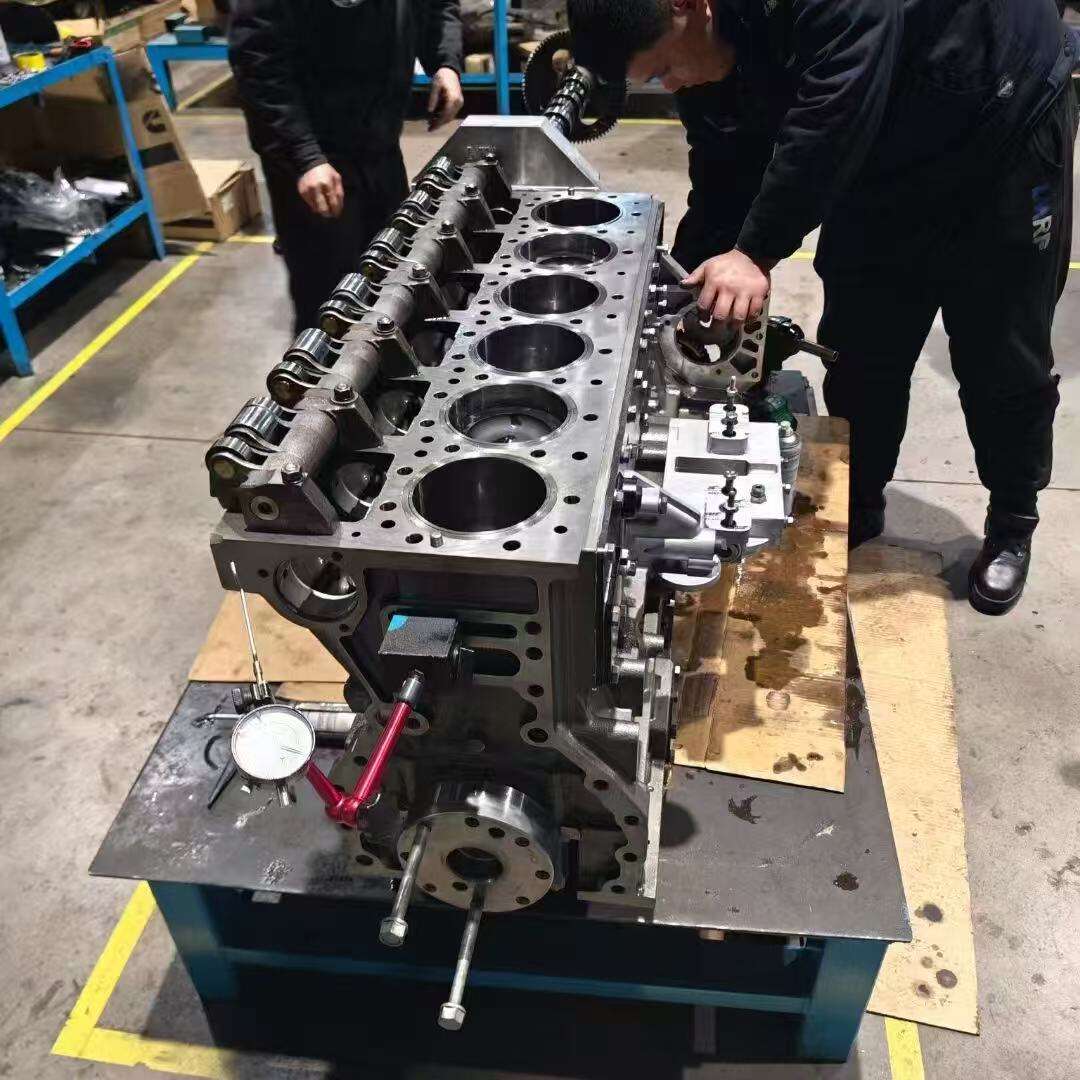

remanufactured engine factory

A remanufactured engine factory stands as a cutting-edge facility dedicated to breathing new life into used engines through sophisticated restoration processes. These state-of-the-art facilities combine advanced manufacturing technology with environmental sustainability, employing skilled technicians who meticulously disassemble, inspect, and rebuild engines to meet or exceed original equipment manufacturer (OEM) specifications. The factory utilizes precision machinery and automated testing equipment to ensure quality control throughout the remanufacturing process. Each engine undergoes thorough cleaning, component replacement, and rigorous testing phases. The facility features specialized departments for disassembly, cleaning, machining, assembly, and testing, all equipped with modern tools and diagnostic equipment. Computer-aided quality control systems monitor every step of the process, while advanced measurement tools ensure precise specifications are met. The factory maintains extensive inventory systems for both cores and new components, enabling efficient production flow and quick turnaround times. Environmental considerations are integrated into the operation through recycling programs, energy-efficient equipment, and waste reduction initiatives. The facility serves various sectors including automotive, industrial, marine, and agricultural markets, providing cost-effective alternatives to new engine purchases while maintaining high performance standards.