low price remanufactured engine

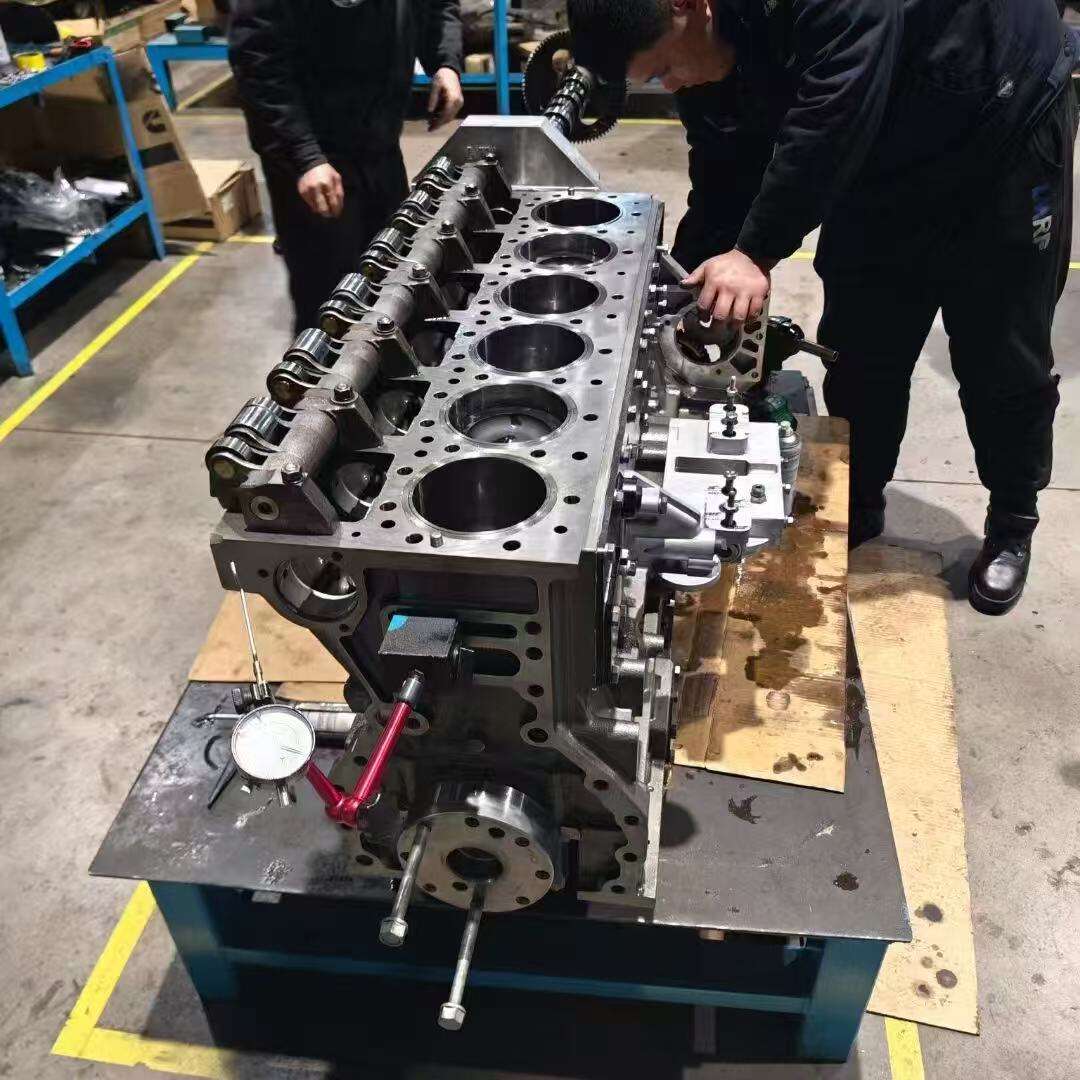

A low price remanufactured engine represents a cost-effective solution for vehicle owners seeking reliable replacement power units. These engines undergo a comprehensive restoration process where skilled technicians completely disassemble, clean, and inspect every component. During remanufacturing, worn parts are replaced with new or reconditioned components that meet or exceed original equipment manufacturer specifications. The process includes precision machining of crucial components like cylinder heads, blocks, and crankshafts, ensuring optimal performance and longevity. These engines feature updated technology and components where applicable, often incorporating improvements that address known issues in the original design. Quality control measures include computerized testing of critical measurements and extensive run testing to verify proper operation. Each remanufactured engine comes with warranty coverage, providing peace of mind to buyers. They are compatible with a wide range of vehicles, from everyday commuter cars to commercial fleet vehicles, and are built to deliver reliable performance while significantly reducing environmental impact through the reuse of core materials.