discount remanufactured engine

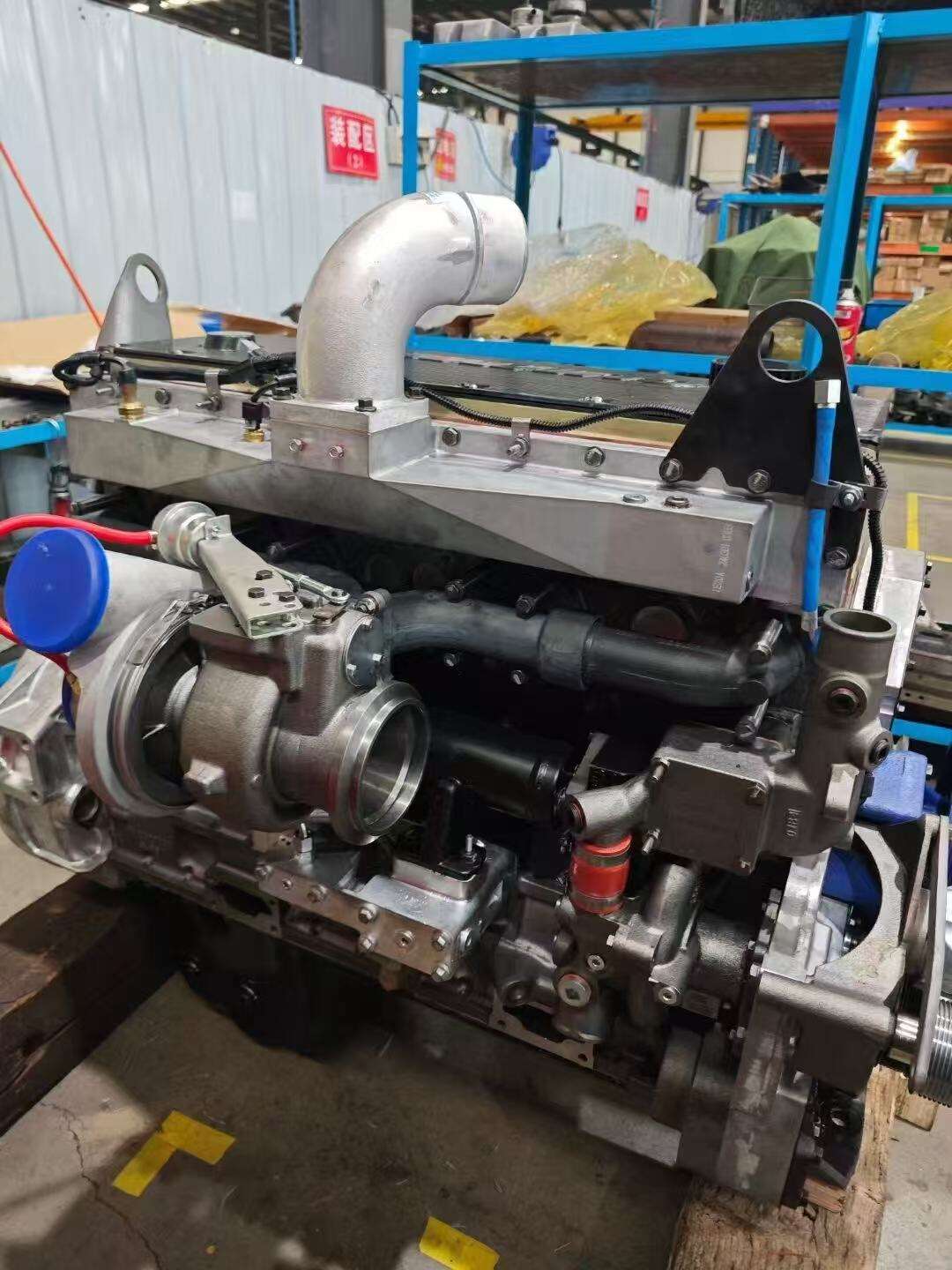

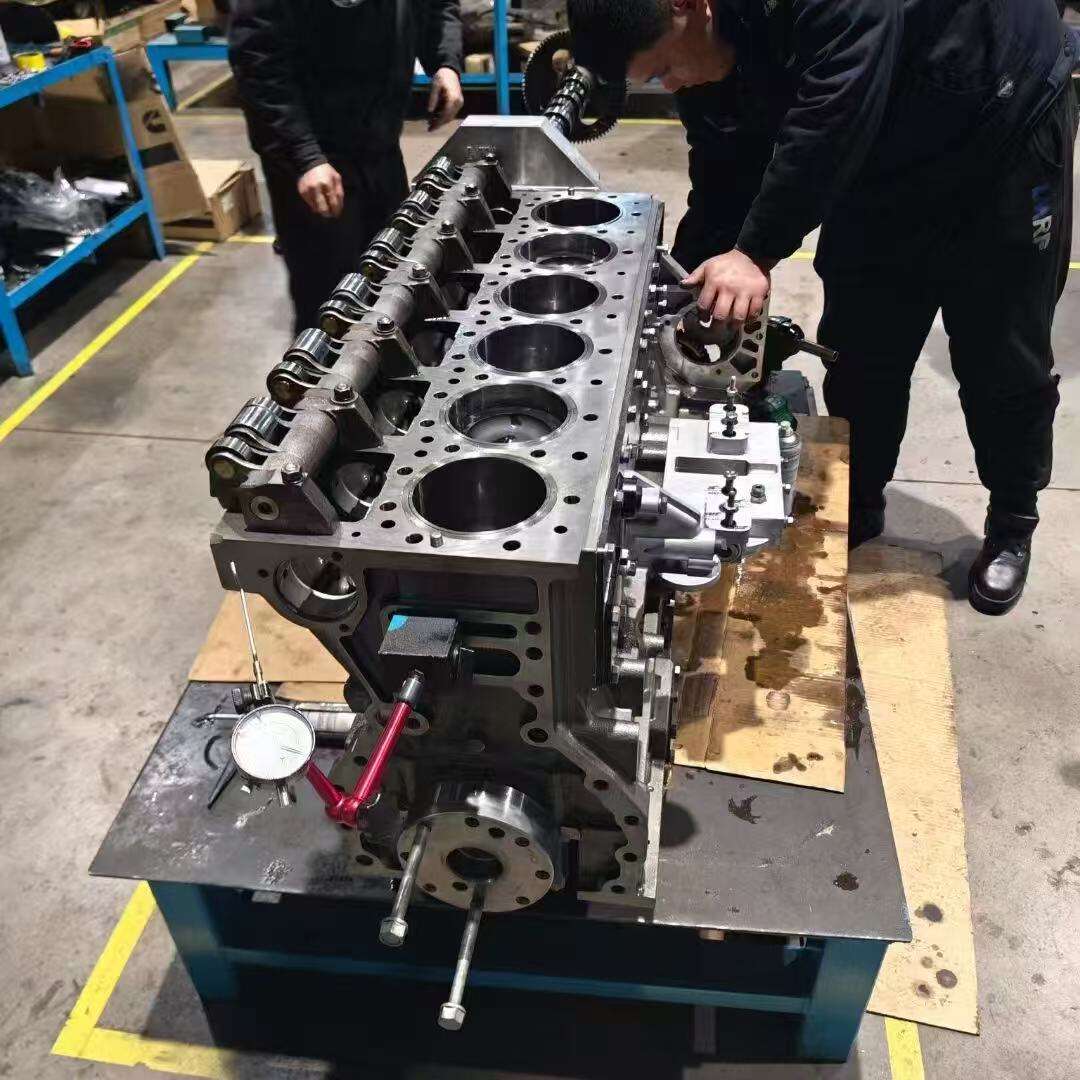

A discount remanufactured engine represents a cost-effective alternative to purchasing a brand new engine, offering reliable performance at a fraction of the cost. These engines undergo a comprehensive restoration process where skilled technicians completely disassemble the core engine, thoroughly clean all components, and replace worn parts with new or reconditioned ones that meet original equipment manufacturer (OEM) specifications. During the remanufacturing process, critical components such as pistons, rings, bearings, timing components, and gaskets are systematically replaced. The cylinder walls are precisely machined and honed to restore proper compression, while the crankshaft is carefully inspected and reground if necessary. Modern quality control measures, including computerized testing equipment, ensure that each remanufactured engine meets strict performance standards. These engines are particularly valuable for vehicle owners seeking a dependable solution for aging or failed engines without the premium cost of new units. They come with warranty coverage and are thoroughly tested before distribution, providing peace of mind to customers while maintaining environmental sustainability through the reuse of core components.