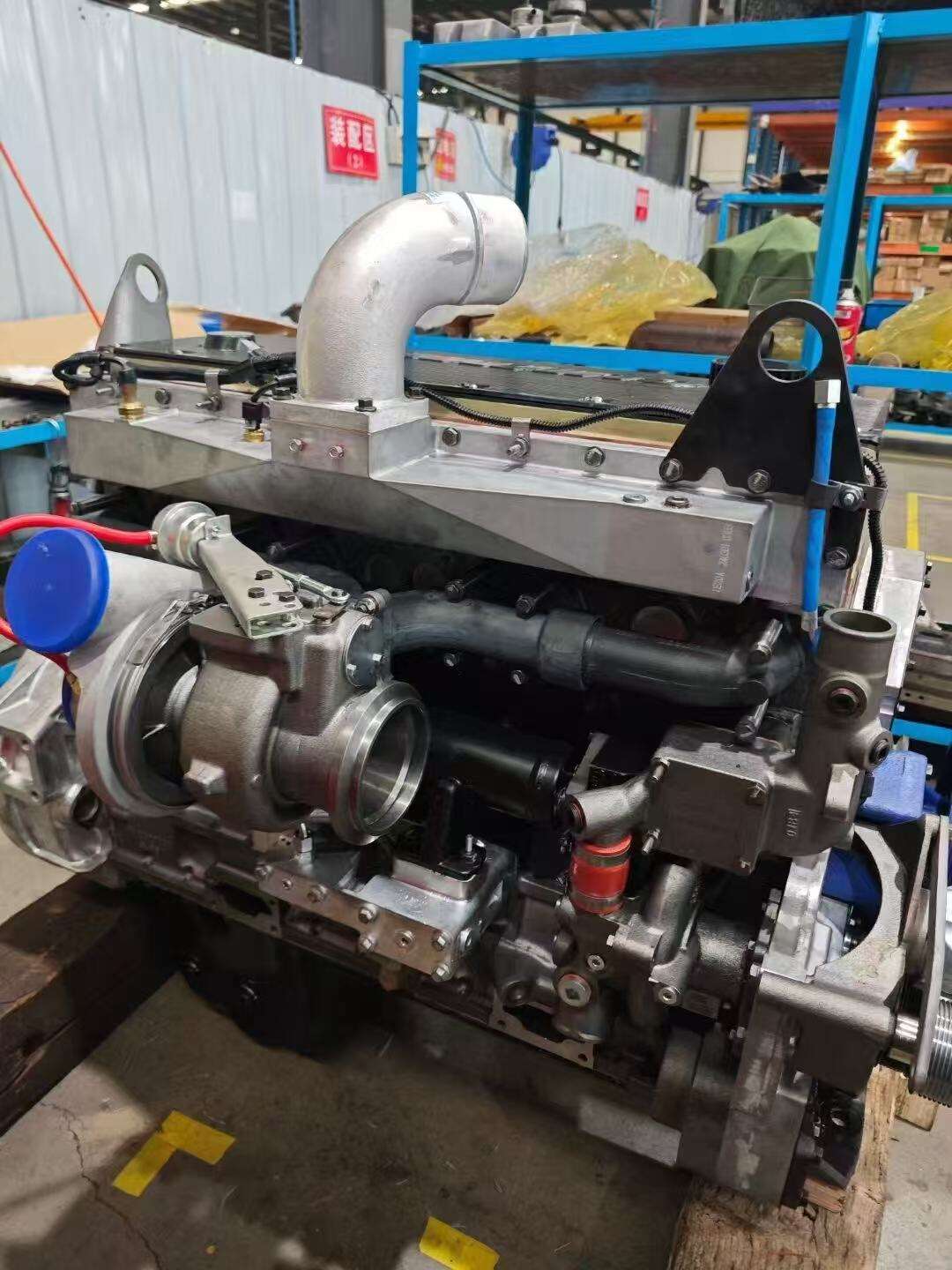

remanufactured engine for sale

A remanufactured engine for sale represents a meticulously restored powertrain unit that undergoes comprehensive rebuilding to meet or exceed original equipment manufacturer specifications. Each engine is completely disassembled, thoroughly cleaned, and carefully inspected before receiving new components and updates to current technological standards. The process involves replacing all wear components, including pistons, rings, bearings, and gaskets, while machining critical surfaces to restore precise tolerances. These engines feature upgraded components where applicable, incorporating modern materials and engineering improvements that weren't available when the original engine was manufactured. The remanufacturing process addresses common failure points and implements solutions to prevent recurring issues. These engines are extensively tested on specialized equipment to ensure proper oil pressure, compression ratios, and overall performance metrics. They're calibrated to deliver optimal fuel efficiency and power output while meeting current emissions standards. Suitable for various applications, from daily drivers to commercial vehicles, these engines come with comprehensive warranties that often match or exceed those of new engines, providing peace of mind and reliable performance for years to come.