buy remanufactured engine

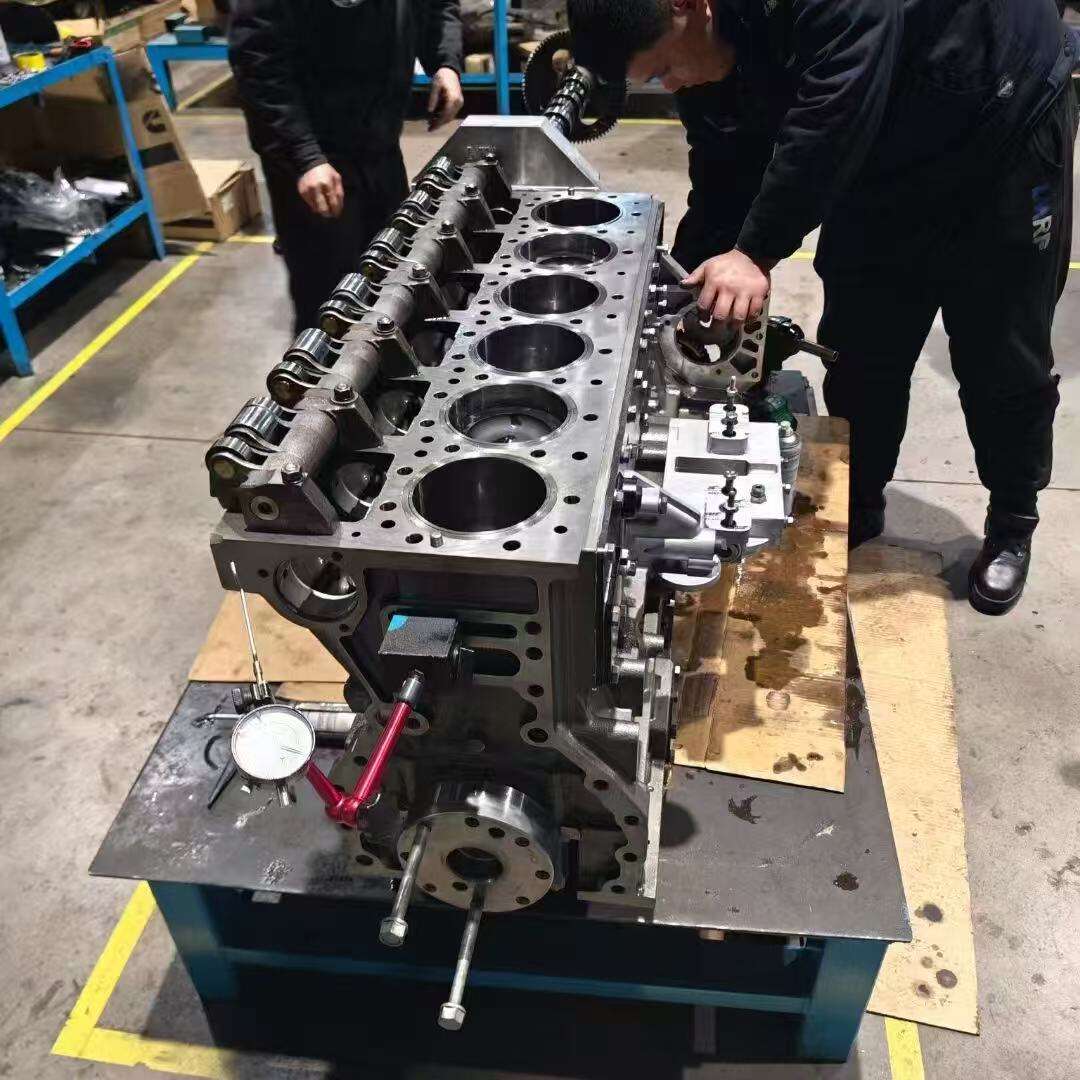

A remanufactured engine represents a cost-effective and environmentally conscious alternative to purchasing a new engine. These engines undergo a comprehensive restoration process, where they are completely disassembled, thoroughly cleaned, and meticulously rebuilt using a combination of new and reconditioned parts. Each component is carefully inspected and tested to meet or exceed original equipment manufacturer (OEM) specifications. The remanufacturing process includes replacing worn components with new parts, updating to current technological standards, and implementing any manufacturer-recommended improvements. These engines are built in specialized facilities using advanced diagnostic equipment and precise quality control measures. They come with warranties comparable to new engines, offering peace of mind to buyers. The process involves replacing critical components such as pistons, rings, bearings, camshafts, and timing components, while the engine block is thoroughly machined and restored to original specifications. Modern remanufactured engines often incorporate updated technology and design improvements that address known issues in the original engine design, potentially offering better performance and reliability than the original.