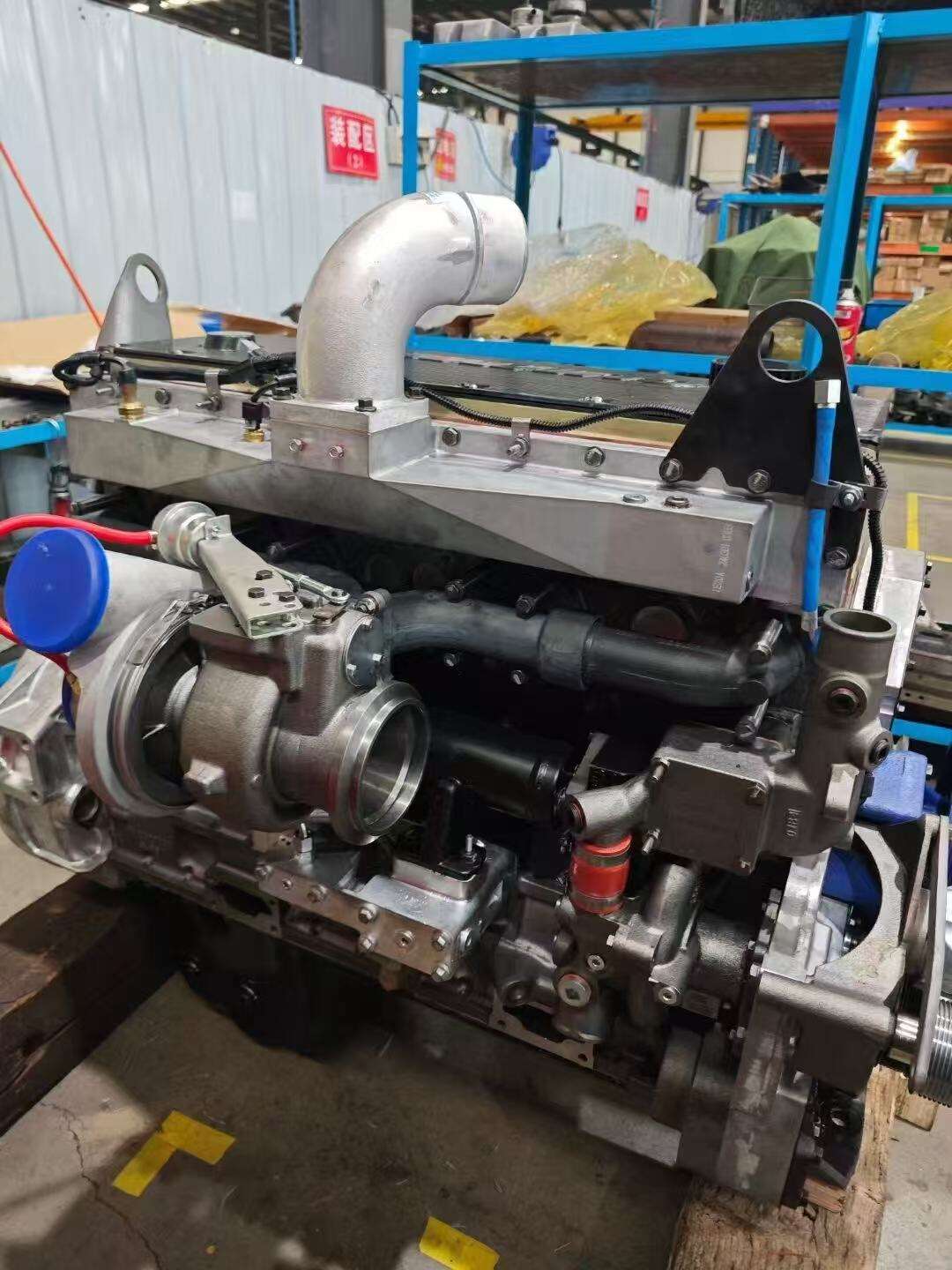

durable remanufactured engine

A durable remanufactured engine represents a meticulously restored power unit that combines reliability with cost-effectiveness. These engines undergo a comprehensive rebuilding process where skilled technicians disassemble, inspect, and restore each component to meet or exceed original equipment manufacturer specifications. The process involves replacing worn parts with new or reconditioned components, updating critical systems, and implementing modern technological improvements where applicable. The engine block is thoroughly cleaned, machined to precise tolerances, and fitted with new pistons, rings, bearings, and gaskets. Advanced testing equipment ensures optimal compression ratios, proper oil flow, and correct timing sequences. These engines feature upgraded materials and contemporary engineering solutions that often result in better performance than their original counterparts. They are particularly valuable in commercial fleet applications, heavy machinery, and personal vehicles where reliability and longevity are paramount. The remanufacturing process not only restores mechanical integrity but also incorporates modern innovations in metallurgy and engineering, resulting in an engine that offers extended service life and improved efficiency.