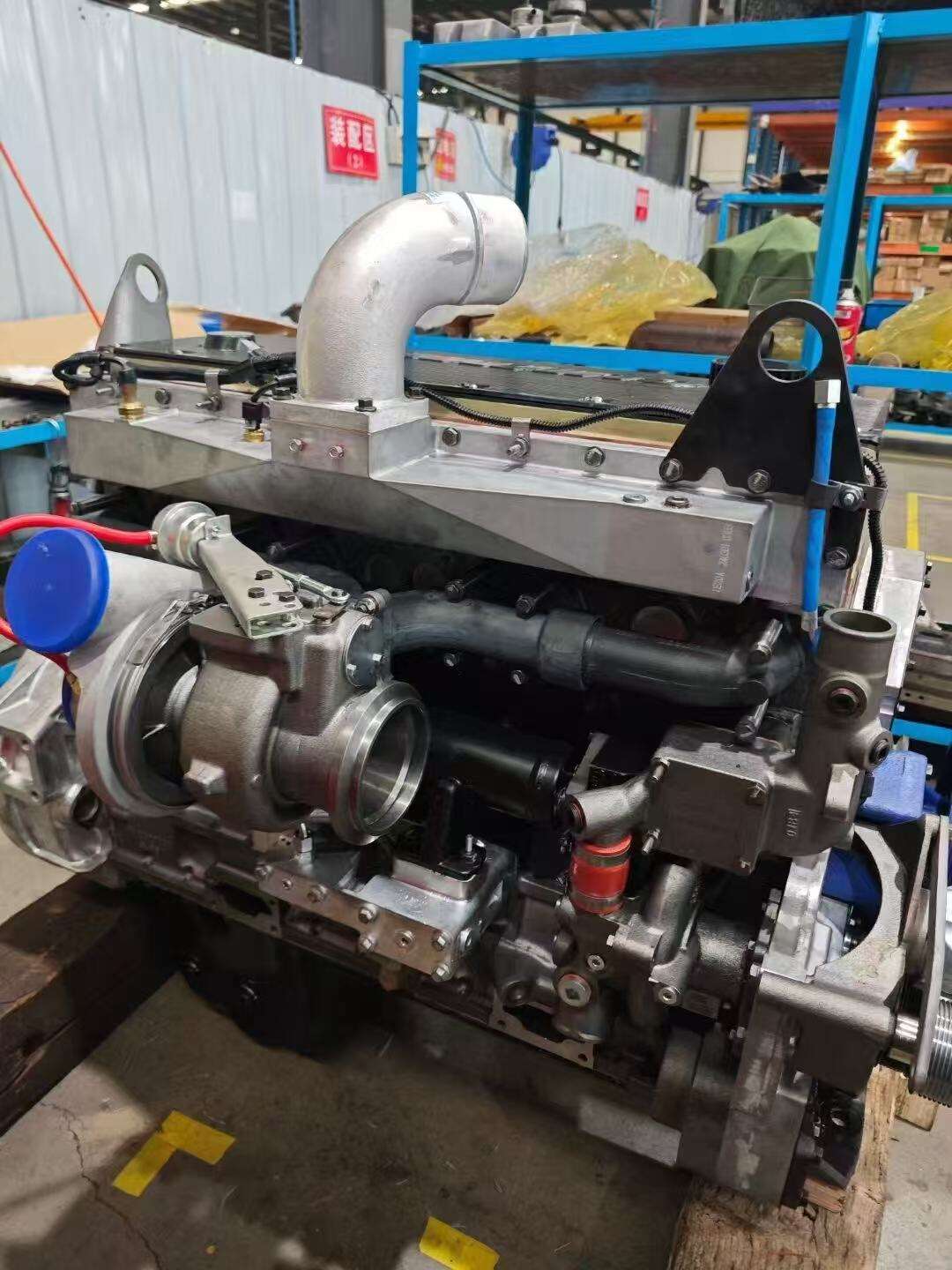

remanufactured engine china

Remanufactured engines from China represent a sustainable and cost-effective solution in the automotive industry, offering meticulously restored power units that meet or exceed original equipment manufacturer (OEM) specifications. These engines undergo a comprehensive rebuilding process that includes thorough cleaning, inspection, and replacement of worn components with new or reconditioned parts. Each engine is disassembled completely, with critical components such as pistons, rings, bearings, timing chains, and gaskets being replaced with quality parts. The process involves precision machining of cylinder heads, blocks, and crankshafts to restore optimal operating conditions. Chinese remanufacturing facilities employ advanced testing equipment and quality control measures to ensure reliability and performance. These engines are particularly notable for their integration of modern technological improvements while maintaining compatibility with original vehicle specifications. The remanufacturing process typically includes upgrading components to address known issues in original designs, resulting in enhanced durability and efficiency. These engines serve various applications, from passenger vehicles to commercial trucks, and are increasingly popular in international markets due to their combination of quality and value.