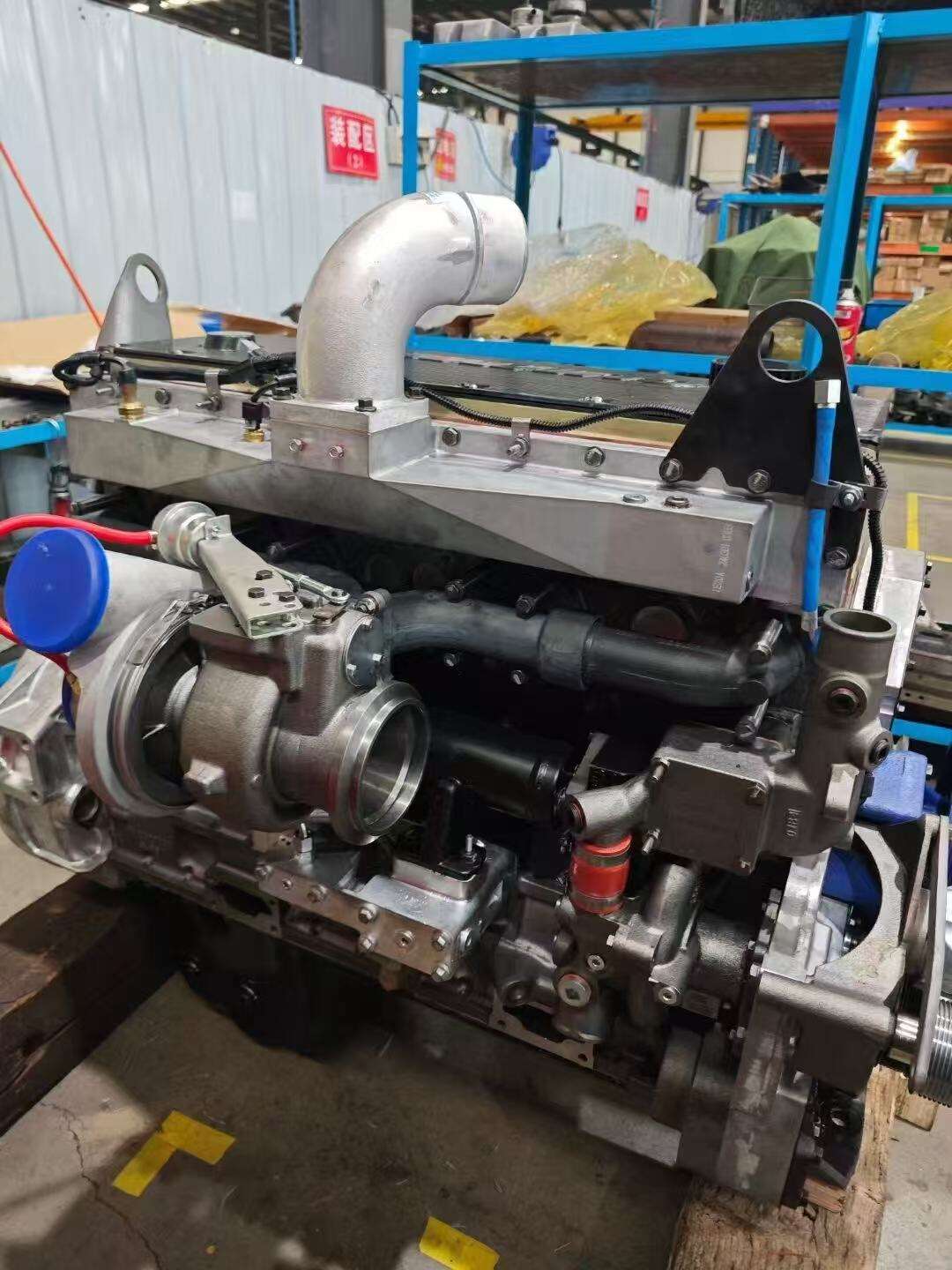

customizable remanufactured engine

A customizable remanufactured engine represents a sustainable and cost-effective solution for vehicle owners seeking reliable power unit replacement. These engines undergo a comprehensive restoration process where they are completely disassembled, thoroughly cleaned, and meticulously rebuilt using a combination of new and reconditioned components. Each engine is customized according to specific performance requirements, making them suitable for various applications from daily drivers to high-performance vehicles. The remanufacturing process involves precision machining, component upgrading, and rigorous testing to ensure optimal performance and longevity. Advanced diagnostic equipment and quality control measures are employed throughout the rebuilding process, guaranteeing that each engine meets or exceeds original equipment manufacturer (OEM) specifications. These engines feature updated technologies and improvements that address known issues in the original design, potentially offering better performance and reliability than the original unit. The customization options available include displacement modifications, compression ratio adjustments, and performance-enhancing components, allowing customers to tailor the engine to their specific needs and preferences.