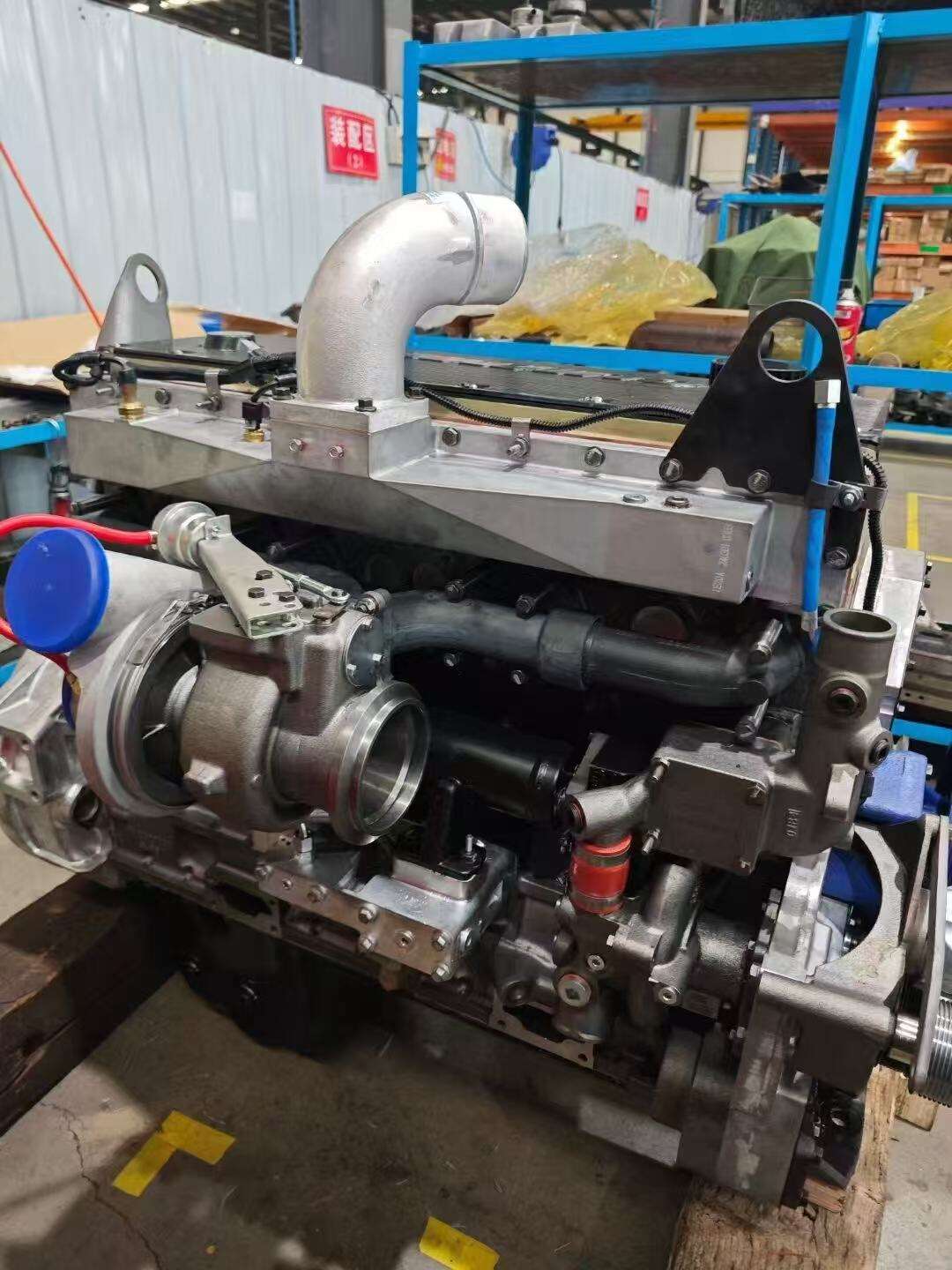

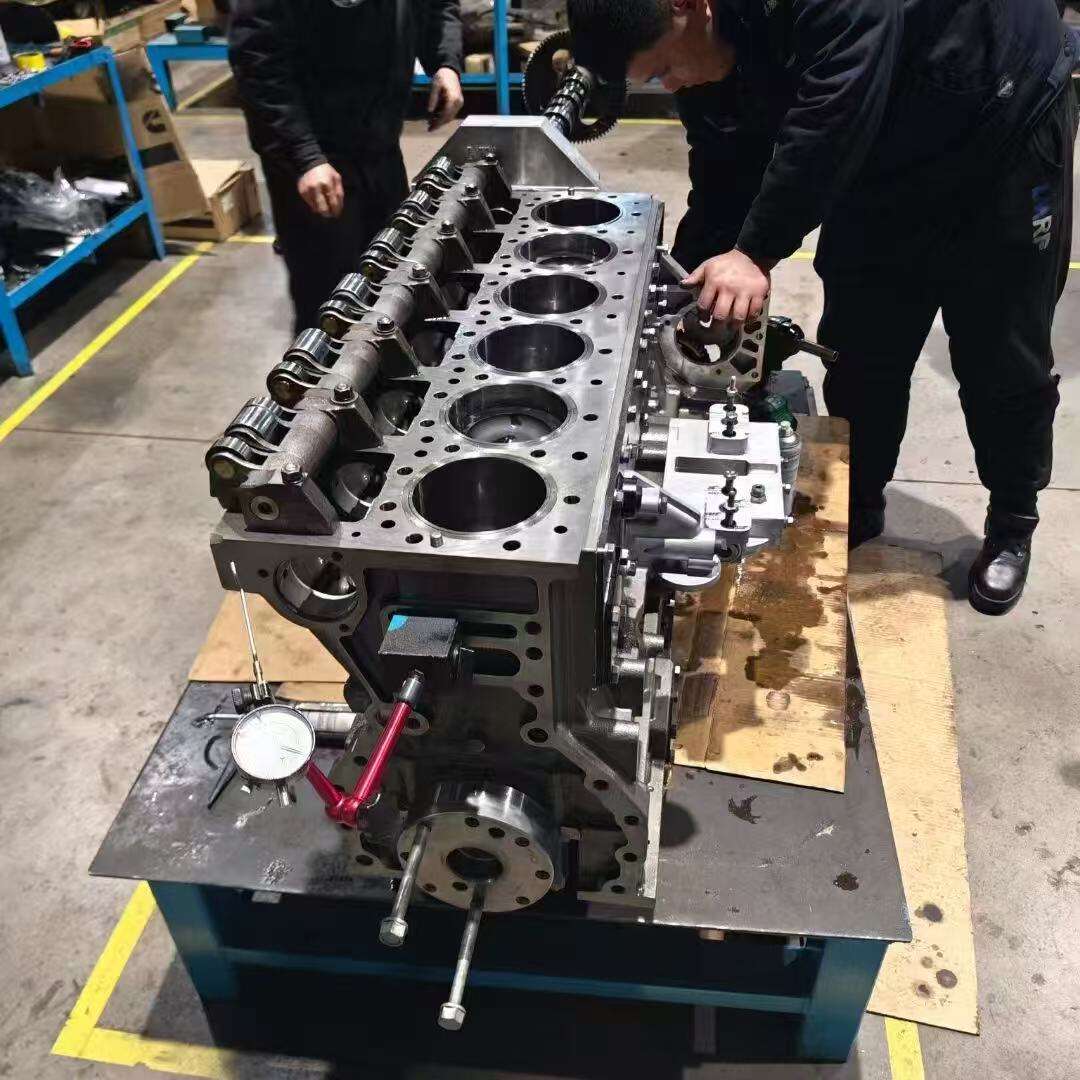

rebuild engine in stock

A rebuild engine in stock represents a meticulously refurbished power unit that combines the reliability of original manufacturing with updated components and modern engineering standards. These engines undergo a comprehensive restoration process, where skilled technicians disassemble, inspect, and replace worn components with new or reconditioned parts that meet or exceed OEM specifications. The rebuilding process includes thorough cleaning, precise machining of critical components, and careful reassembly using updated gaskets, seals, and bearings. Each rebuild engine features restored cylinder heads, renewed piston rings, polished crankshafts, and recalibrated fuel delivery systems. The process also involves modern technological upgrades where applicable, such as improved valve materials or enhanced cooling system components. These engines are thoroughly tested on specialized equipment to ensure proper compression ratios, oil pressure, and overall performance before being made available for purchase. Available for various vehicle makes and models, rebuild engines in stock offer an economical alternative to new engine replacement while maintaining high-quality standards and reliability. They come with warranty coverage and are ready for immediate installation, minimizing vehicle downtime.