rebuild engine manufacturers

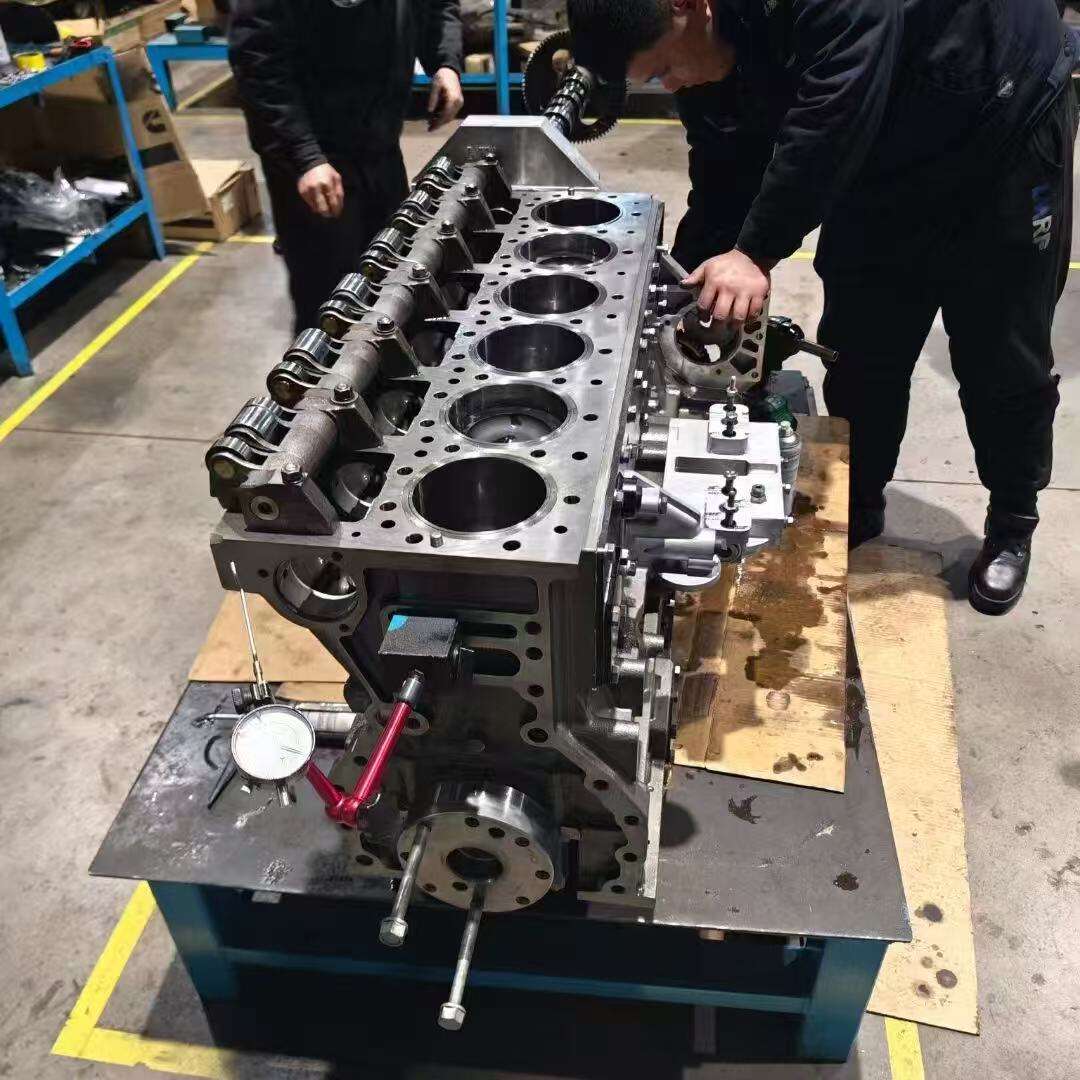

Rebuild engine manufacturers play a crucial role in the automotive industry by providing refurbished and remanufactured engines that meet or exceed original equipment manufacturer (OEM) specifications. These specialized companies employ advanced engineering processes and state-of-the-art technology to completely disassemble, clean, inspect, and rebuild engines to their original performance standards. The manufacturing process involves thorough quality control measures, including precise machining, component replacement, and extensive testing procedures. These manufacturers utilize modern diagnostic equipment and specialized tools to ensure each rebuilt engine meets strict quality standards. They source high-quality replacement parts and employ skilled technicians who possess extensive knowledge of various engine types and models. The rebuilt engines undergo rigorous performance testing on specialized dynamometer equipment to verify proper operation, power output, and efficiency. These manufacturers often provide warranties comparable to new engines, making them a cost-effective alternative for vehicle owners and fleet operators. Their services extend across various applications, including passenger vehicles, commercial trucks, industrial equipment, and marine vessels.