rebuild engine for sale

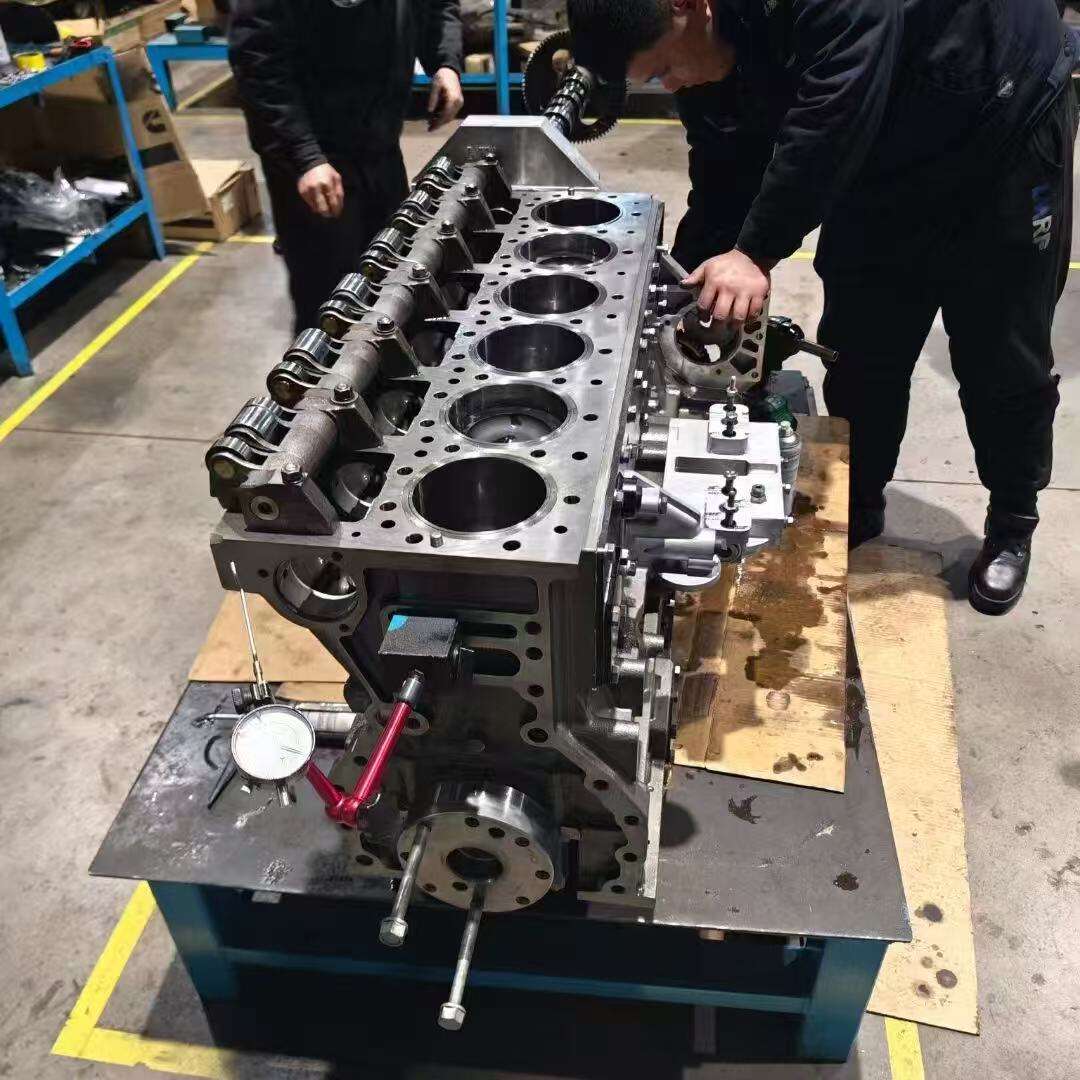

A rebuild engine for sale represents a meticulously refurbished power unit that has been completely disassembled, inspected, and reconstructed to meet or exceed original manufacturer specifications. These engines undergo a comprehensive restoration process where worn components are replaced with new or reconditioned parts, ensuring optimal performance and reliability. The rebuilding process involves thorough cleaning, precise machining of vital components, and careful reassembly using modern techniques and quality materials. Each rebuilt engine features updated gaskets, seals, and bearings, while critical components such as pistons, connecting rods, and crankshafts are carefully evaluated and either restored or replaced. The cylinder heads are resurfaced, and valve trains are adjusted to ensure proper operation. These engines incorporate the latest technological improvements and updates, often resulting in better performance than the original unit. They are extensively tested for compression, oil pressure, and overall functionality before being offered for sale, providing customers with a cost-effective alternative to new engine replacement.