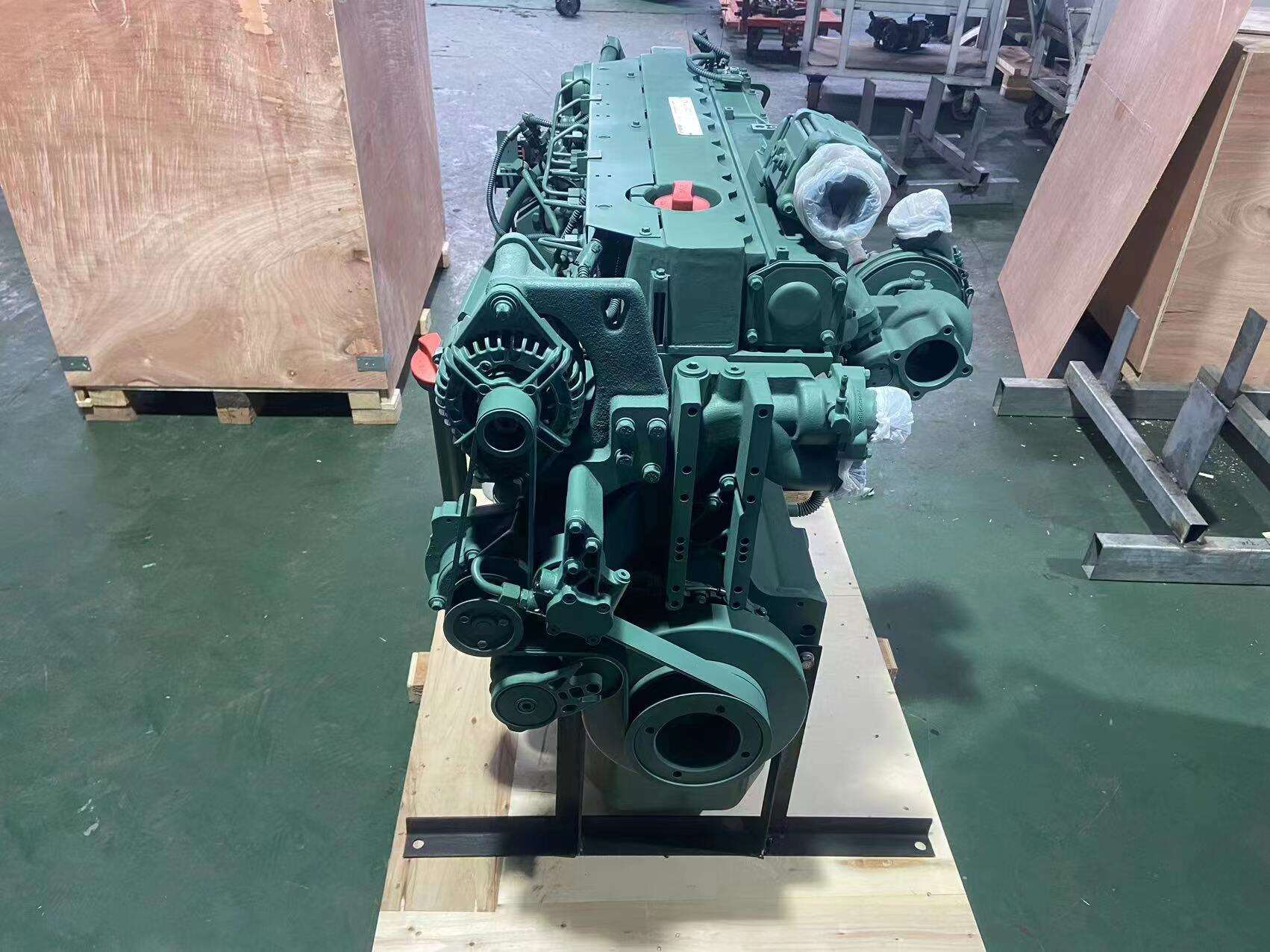

wholesale loader engine

The wholesale loader engine represents a significant advancement in industrial machinery technology, designed specifically for heavy-duty applications in warehousing and logistics operations. This robust power system combines cutting-edge engineering with reliable performance, delivering exceptional output for various loading applications. The engine features a sophisticated fuel injection system that optimizes fuel consumption while maintaining powerful torque across different operating conditions. With its advanced thermal management system, the engine maintains optimal operating temperatures even under prolonged use, ensuring consistent performance and extended service life. The engine's modular design facilitates easy maintenance and repairs, reducing downtime and operational costs. It incorporates state-of-the-art emission control technology, meeting strict environmental standards while delivering maximum power output. The electronic control unit (ECU) provides precise monitoring and adjustment of engine parameters, ensuring optimal performance in diverse working conditions. This versatile engine powers various loader types, from compact warehouse machines to large-scale industrial equipment, making it an ideal choice for wholesale operations of any size.