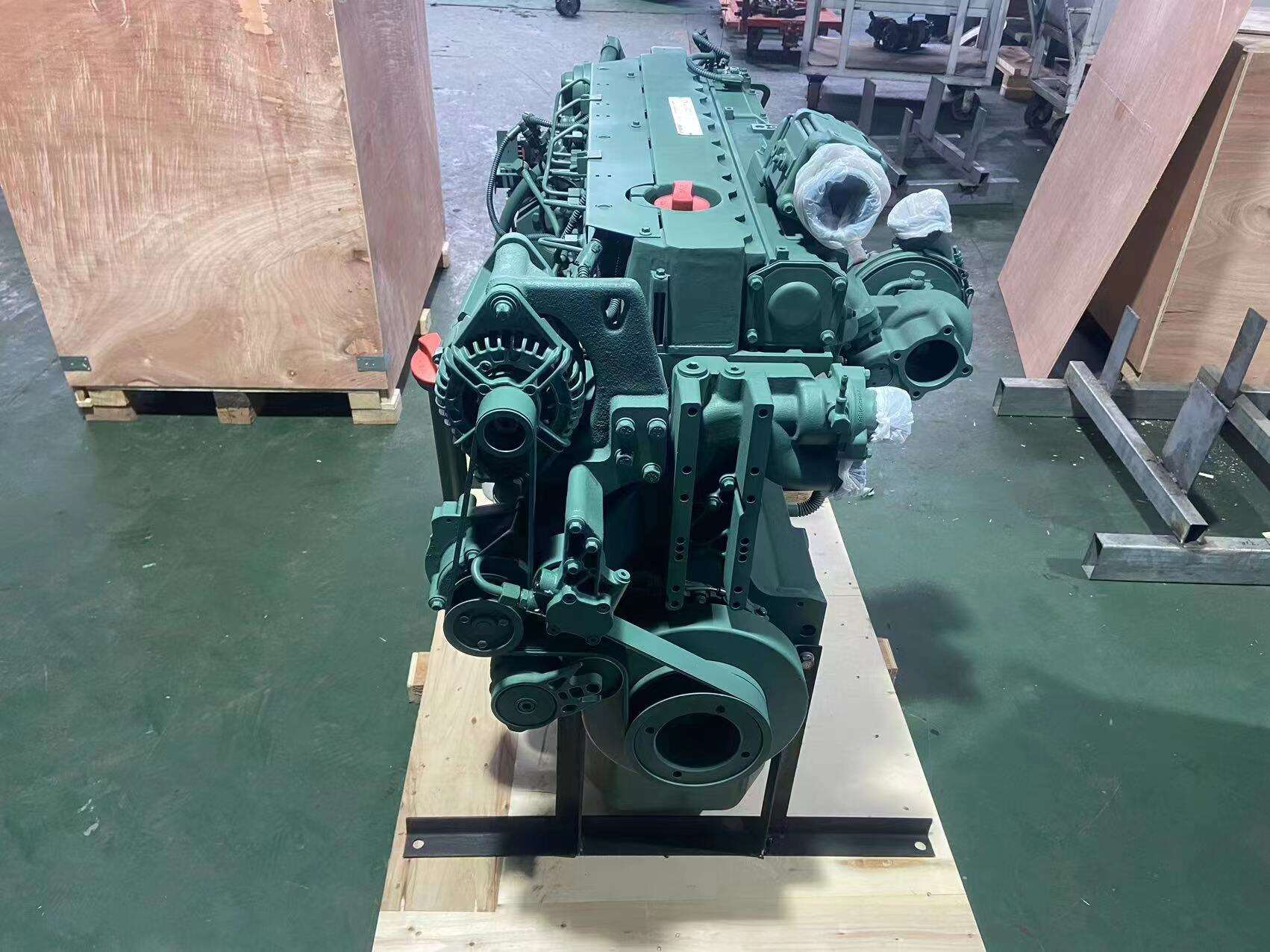

china loader engine

The China loader engine represents a significant advancement in industrial power systems, combining robust performance with cost-effective operation. This powerhouse component delivers reliable mechanical energy for various loader applications, featuring advanced fuel injection systems and optimized combustion chambers that ensure efficient power delivery. The engine's design incorporates modern thermal management systems and precision-engineered components, enabling it to maintain optimal operating temperatures while minimizing fuel consumption. With displacement ranges typically between 4.5L to 7.0L, these engines generate substantial torque output, making them ideal for heavy-duty loading operations. The integration of electronic control units (ECU) allows for precise fuel management and enhanced performance monitoring, while the strengthened crankshaft and connecting rods ensure durability under demanding conditions. These engines comply with international emission standards through the implementation of advanced exhaust gas treatment systems, making them environmentally responsible choices for construction and material handling applications. The versatility of China loader engines extends to their adaptability across different loader sizes and applications, from small utility loaders to large construction equipment, providing a reliable power solution for various industrial needs.