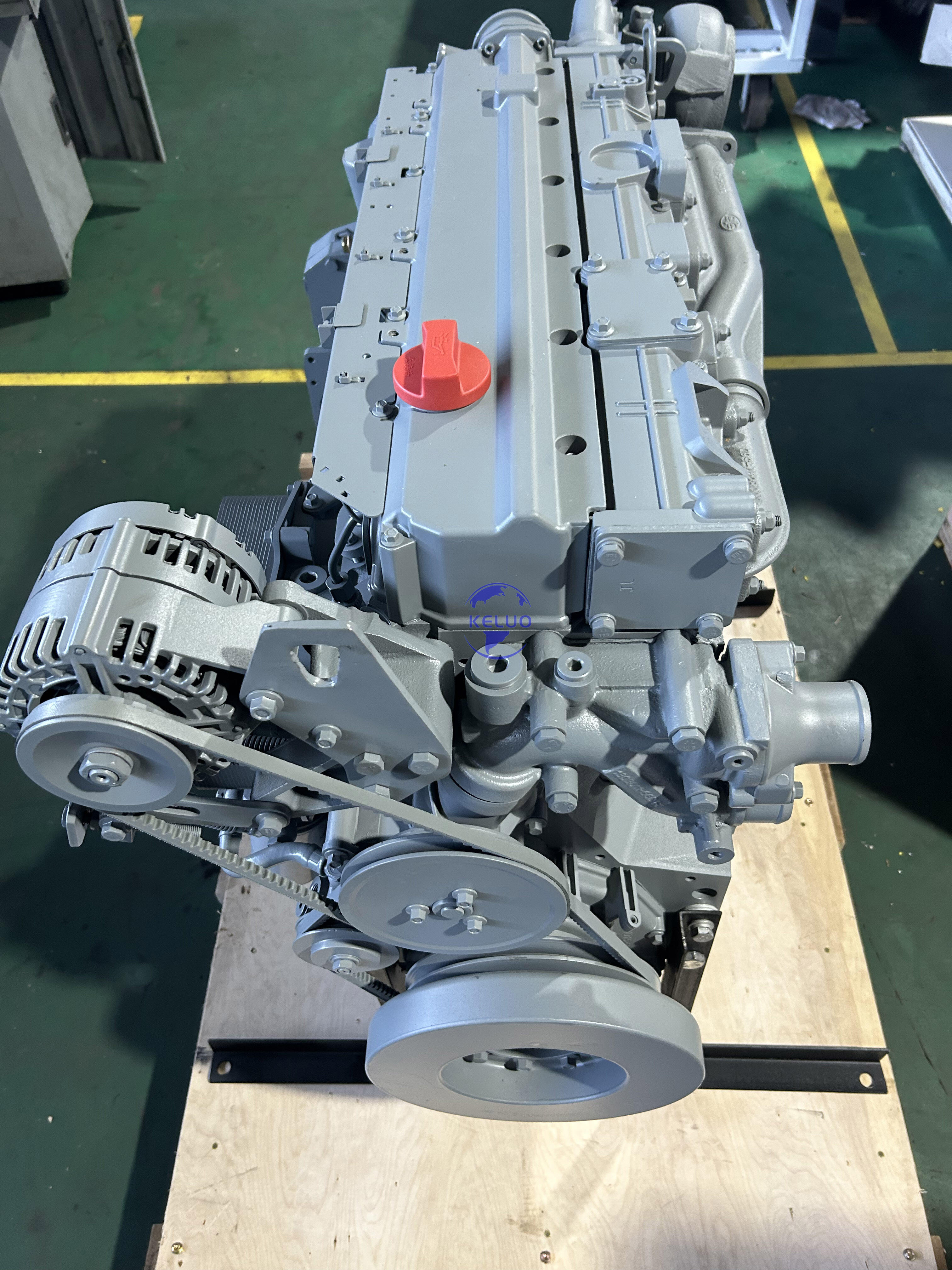

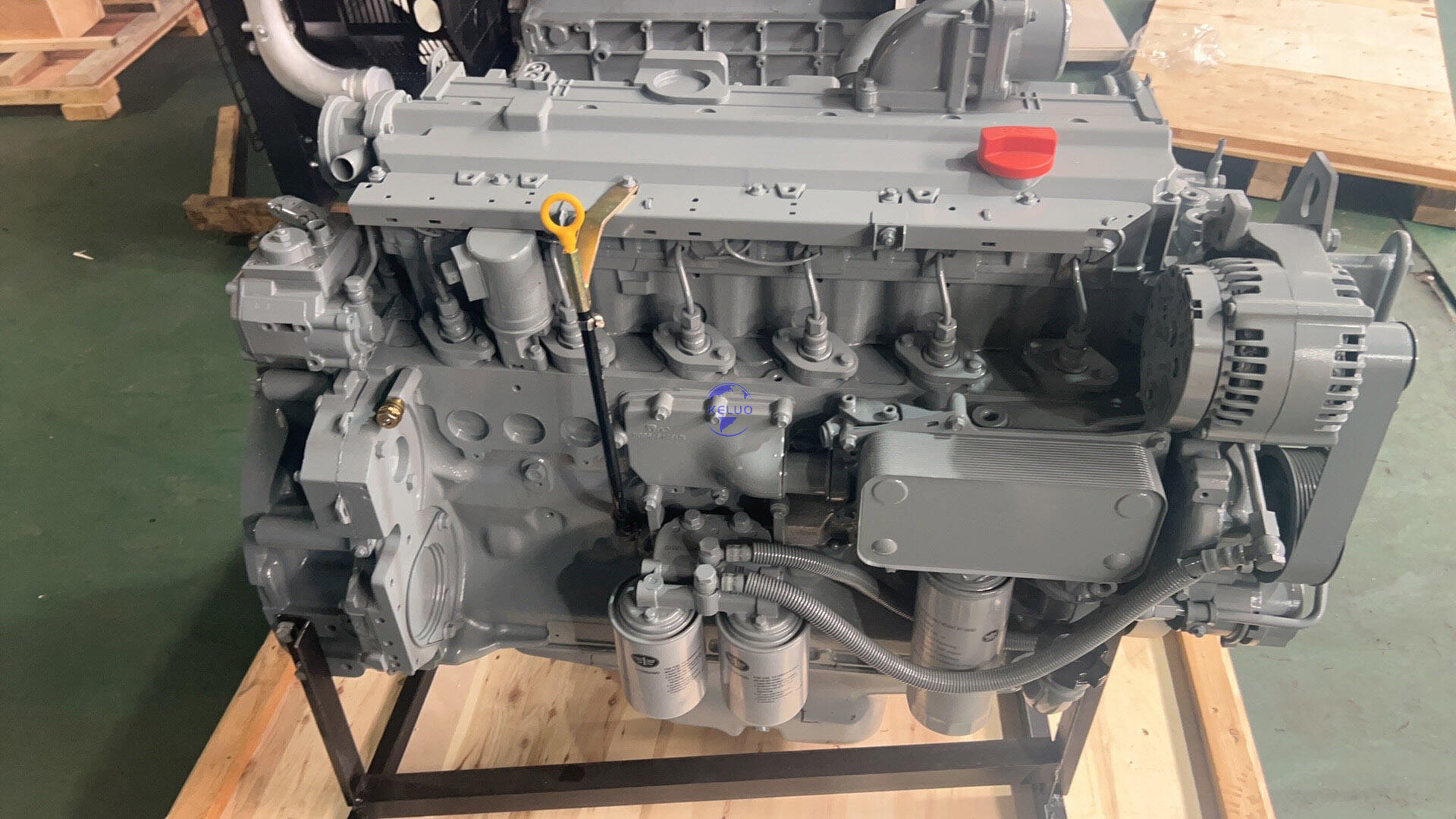

newest excavator engine

The newest excavator engine represents a significant leap forward in construction equipment technology, combining enhanced power output with unprecedented fuel efficiency. This state-of-the-art powerplant features a revolutionary direct injection system that optimizes fuel combustion, resulting in reduced emissions while maintaining superior performance. The engine incorporates advanced thermal management technology, utilizing a smart cooling system that automatically adjusts based on operating conditions. With its compact design, the engine delivers an impressive power-to-weight ratio, generating up to 512 horsepower while maintaining a smaller footprint than previous models. The integration of intelligent electronic controls enables real-time performance monitoring and automatic adjustments to maximize efficiency across various operating conditions. This engine also features a robust filtration system that extends service intervals and enhances reliability in demanding environments. The innovative start-stop technology automatically shuts down the engine during idle periods, significantly reducing fuel consumption and wear. Notably, the engine's modular design facilitates easier maintenance access and quicker component replacement, minimizing downtime and reducing operational costs. These features make it particularly suitable for heavy-duty applications in construction, mining, and large-scale earthmoving operations.