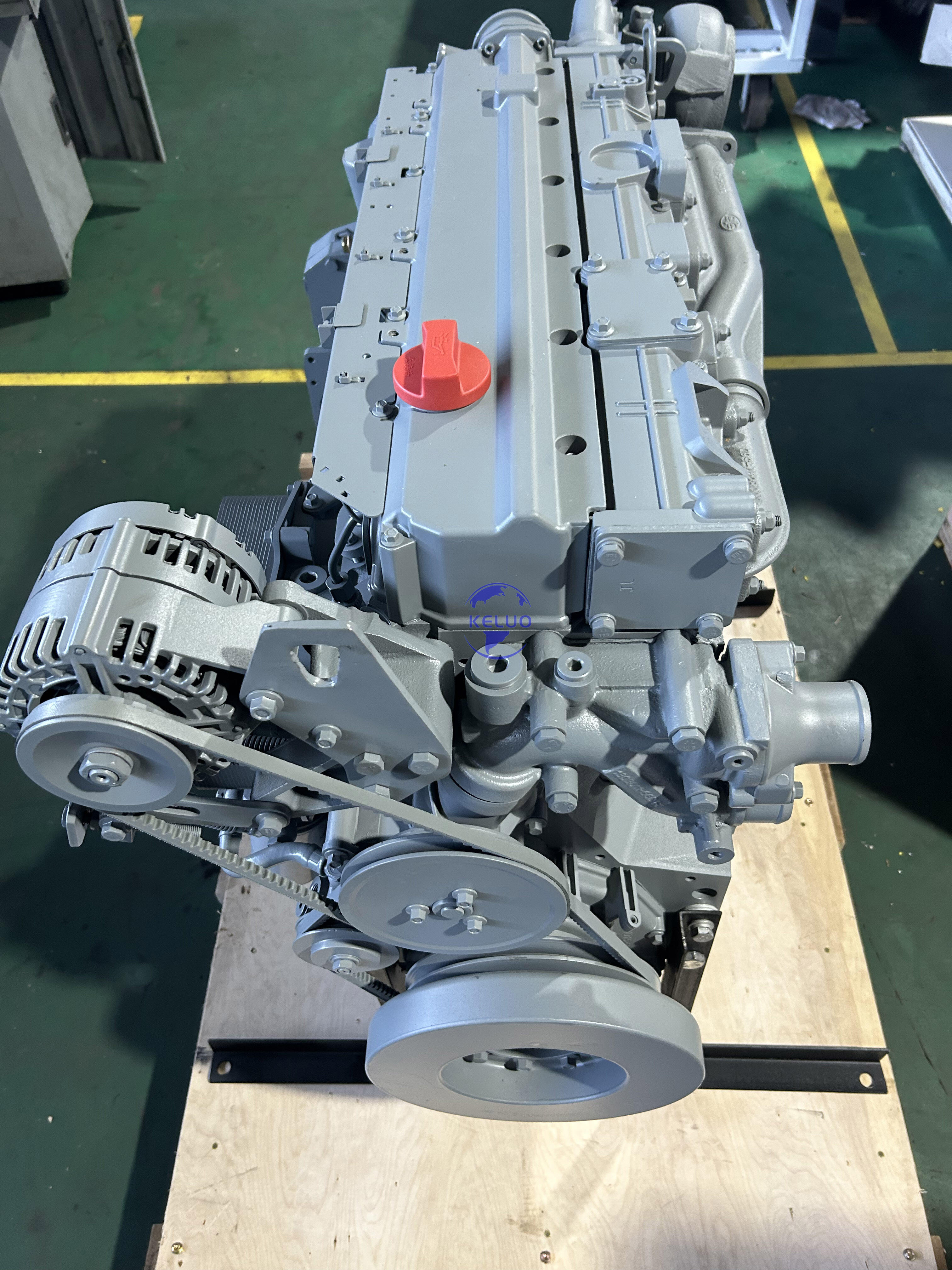

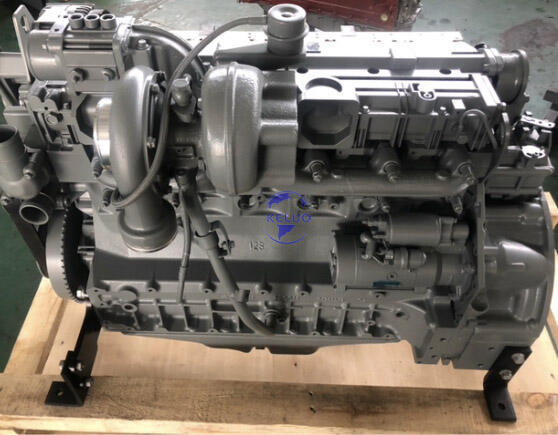

excavator engine china

The excavator engine china represents a significant advancement in construction machinery power systems, combining robust performance with cost-effective manufacturing. These engines are specifically engineered to meet the demanding requirements of heavy-duty excavation operations while maintaining optimal fuel efficiency. Built with precision engineering and advanced manufacturing techniques, these power units deliver consistent performance across various operating conditions. The engines feature sophisticated fuel injection systems, optimized combustion chambers, and state-of-the-art thermal management systems that ensure reliable operation in challenging environments. They are designed to provide high torque at low RPMs, which is crucial for excavator operations requiring sustained power for digging and lifting. The integration of modern electronic control systems allows for precise power delivery and improved emission control, meeting international environmental standards. These engines are also equipped with advanced filtration systems that protect internal components from contamination, extending service life and reducing maintenance requirements. With power outputs ranging from 60 to 500 horsepower, these engines cater to various excavator sizes and applications, from compact urban construction to large-scale mining operations.