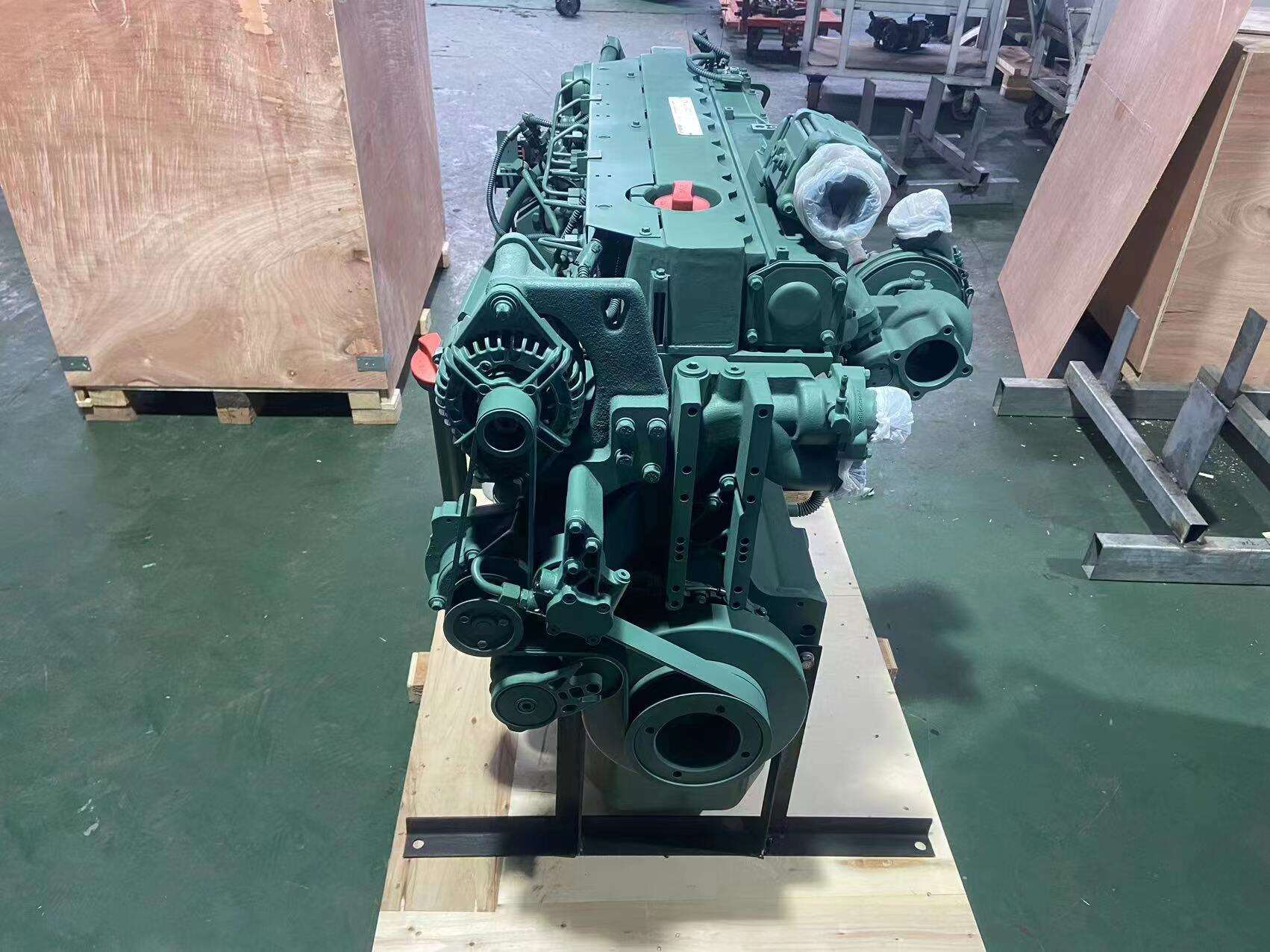

customized loader engine

A customized loader engine represents a breakthrough in material handling and industrial automation technology. This advanced system combines precision engineering with adaptable programming to create a versatile loading solution that can be tailored to specific operational requirements. The engine features state-of-the-art sensors and control systems that enable precise positioning and movement, while its modular design allows for easy integration with existing infrastructure. The system's core functions include automated material transfer, intelligent load distribution, and real-time performance monitoring. Advanced safety protocols are integrated throughout the operation, including emergency stop mechanisms and collision avoidance systems. The engine's technological capabilities extend to variable speed control, dynamic load balancing, and predictive maintenance algorithms. Its applications span across multiple industries, from manufacturing and warehousing to logistics and distribution centers. The system can handle diverse load types and sizes, making it particularly valuable for operations requiring frequent changeovers or handling multiple product lines. Additionally, the engine's smart connectivity features enable seamless integration with Industry 4.0 environments, providing valuable data analytics and performance metrics for continuous improvement.