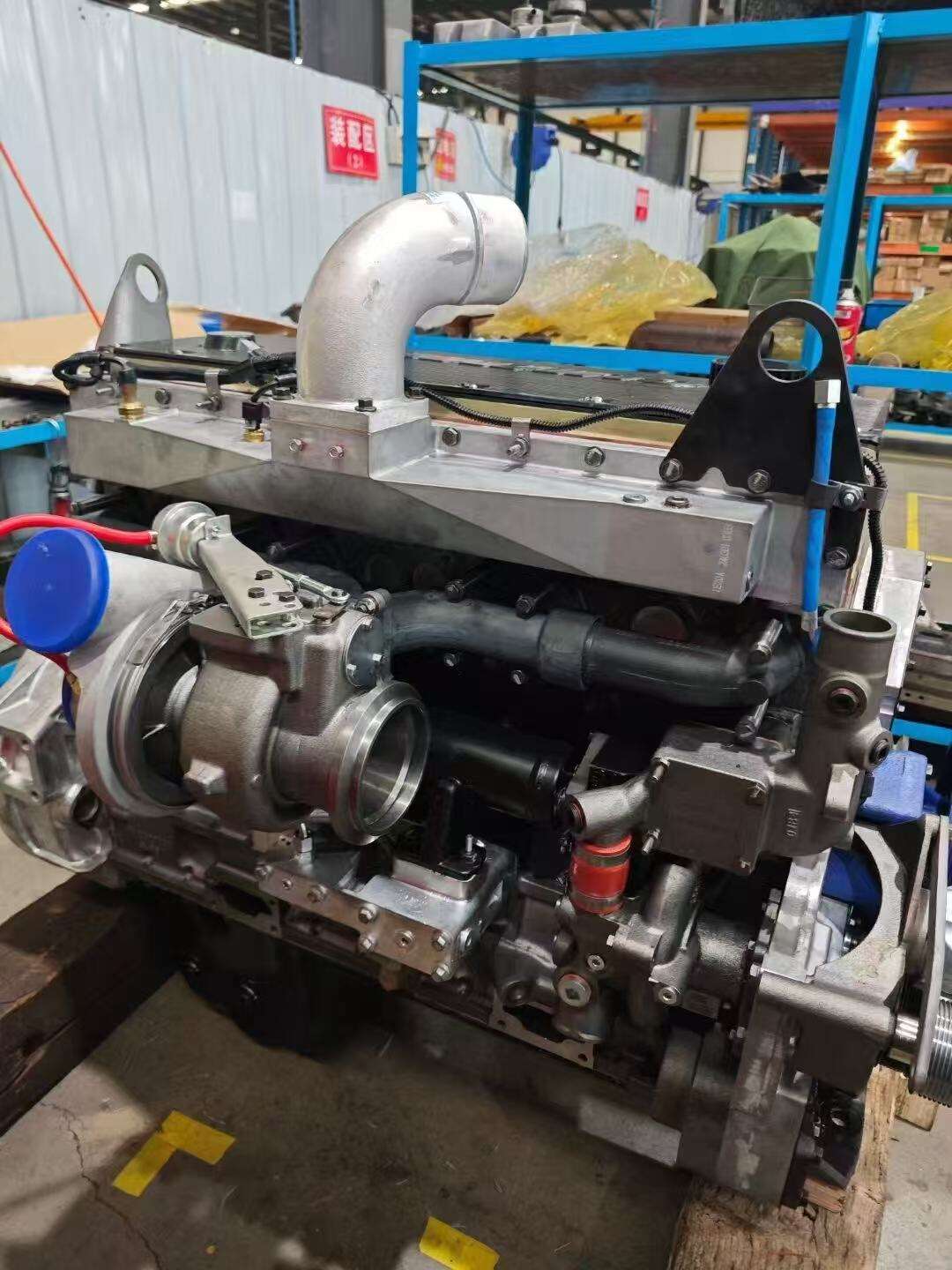

china rebuild engine manufacturers

China rebuild engine manufacturers have established themselves as leading providers of remanufactured engines, combining advanced engineering expertise with cost-effective solutions. These manufacturers employ state-of-the-art facilities equipped with precision machinery and testing equipment to restore engines to their original specifications. The process involves complete disassembly, thorough inspection, replacement of worn components, and reassembly using updated manufacturing techniques. These facilities maintain strict quality control measures, ensuring each rebuilt engine meets or exceeds OEM standards. The manufacturers specialize in various engine types, from passenger vehicles to heavy-duty industrial applications, offering customization options to meet specific requirements. They utilize advanced cleaning technologies, modern machining processes, and precise calibration equipment to ensure optimal performance. The rebuilt engines undergo rigorous testing procedures, including dynamometer testing, compression testing, and oil pressure verification, guaranteeing reliability and durability. These manufacturers also integrate sustainable practices by recycling and reconditioning viable components, contributing to environmental conservation while maintaining high-quality standards.