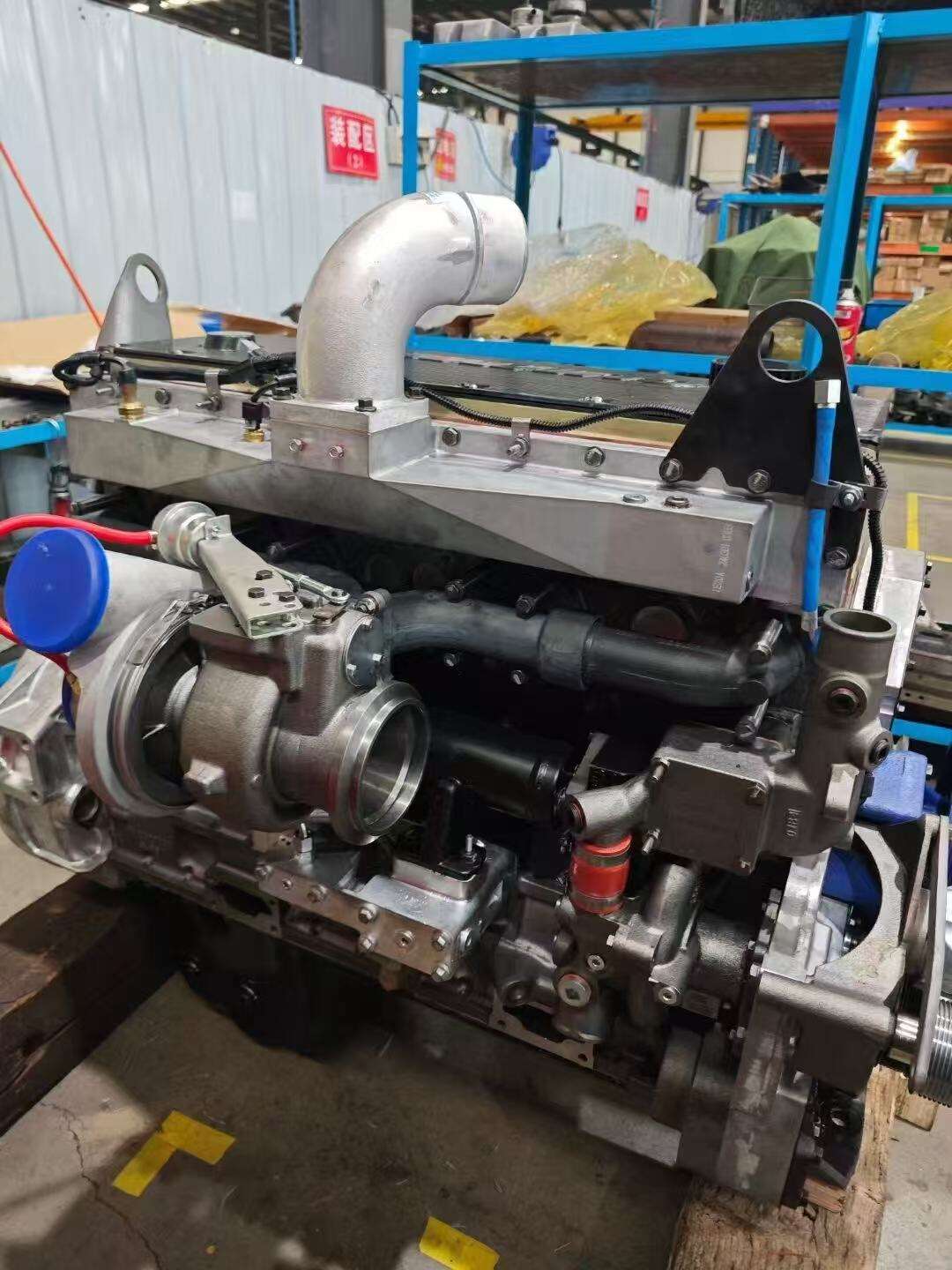

customized remanufactured engine

A customized remanufactured engine represents a meticulously rebuilt power unit that combines reliability with personalized performance specifications. These engines undergo a comprehensive restoration process where experienced technicians disassemble, inspect, and rebuild them using a mixture of new and reconditioned components. Each engine is carefully tailored to meet specific performance requirements, whether for increased horsepower, enhanced fuel efficiency, or improved durability. The process involves precise machining of critical components, including the cylinder heads, engine block, and crankshaft, all performed to exact factory specifications. Advanced diagnostic equipment ensures all tolerances meet or exceed original equipment manufacturer standards. The customization aspect allows for the integration of upgraded components, such as forged pistons, performance camshafts, or strengthened connecting rods, depending on the intended application. These engines incorporate modern technological improvements while maintaining the original design's integrity, resulting in a power unit that often outperforms its factory counterpart. The remanufacturing process includes thorough testing under simulated load conditions, ensuring optimal performance and reliability before installation. This approach not only provides a cost-effective alternative to new engines but also offers the flexibility to enhance specific performance characteristics according to individual needs.