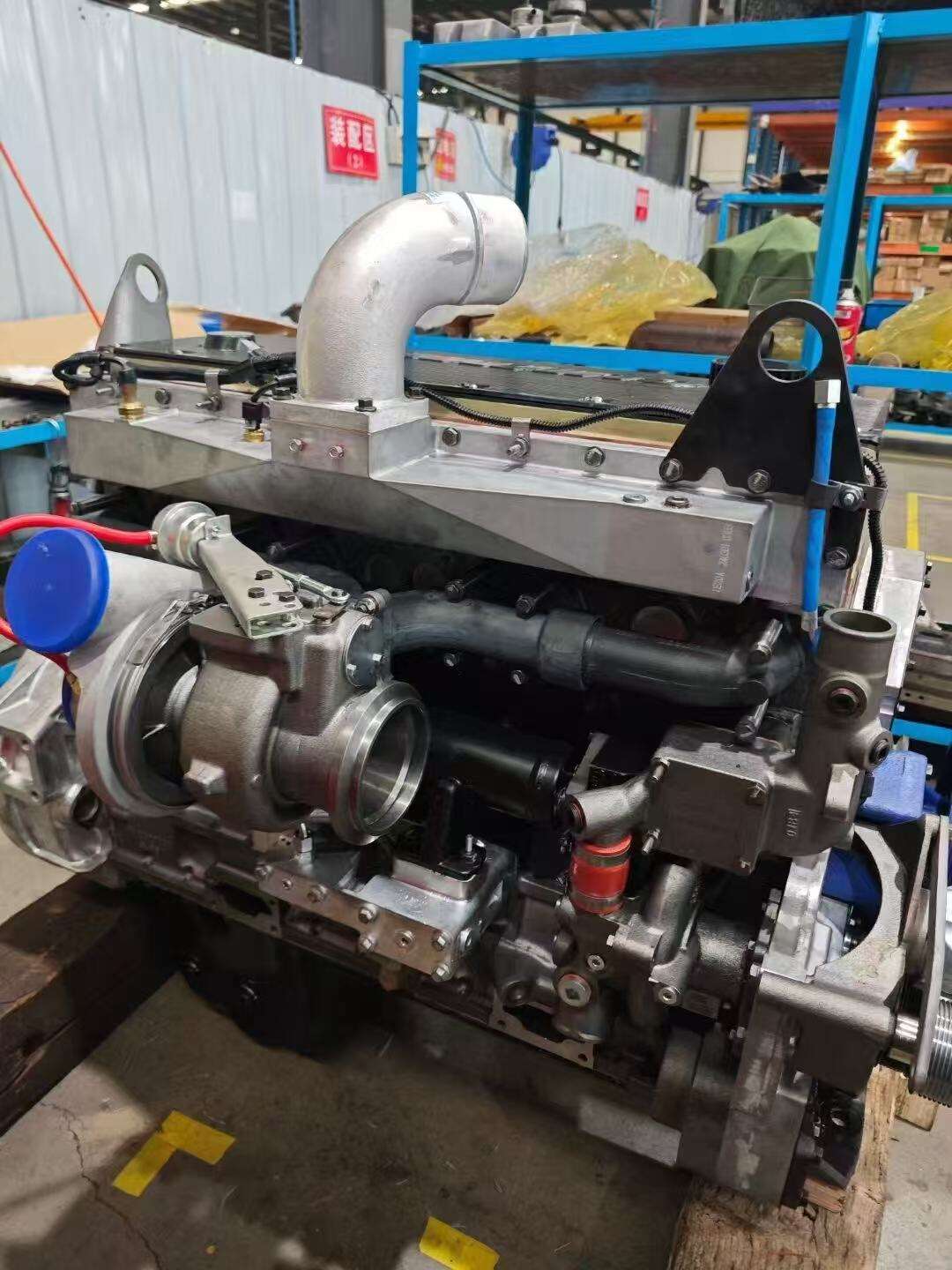

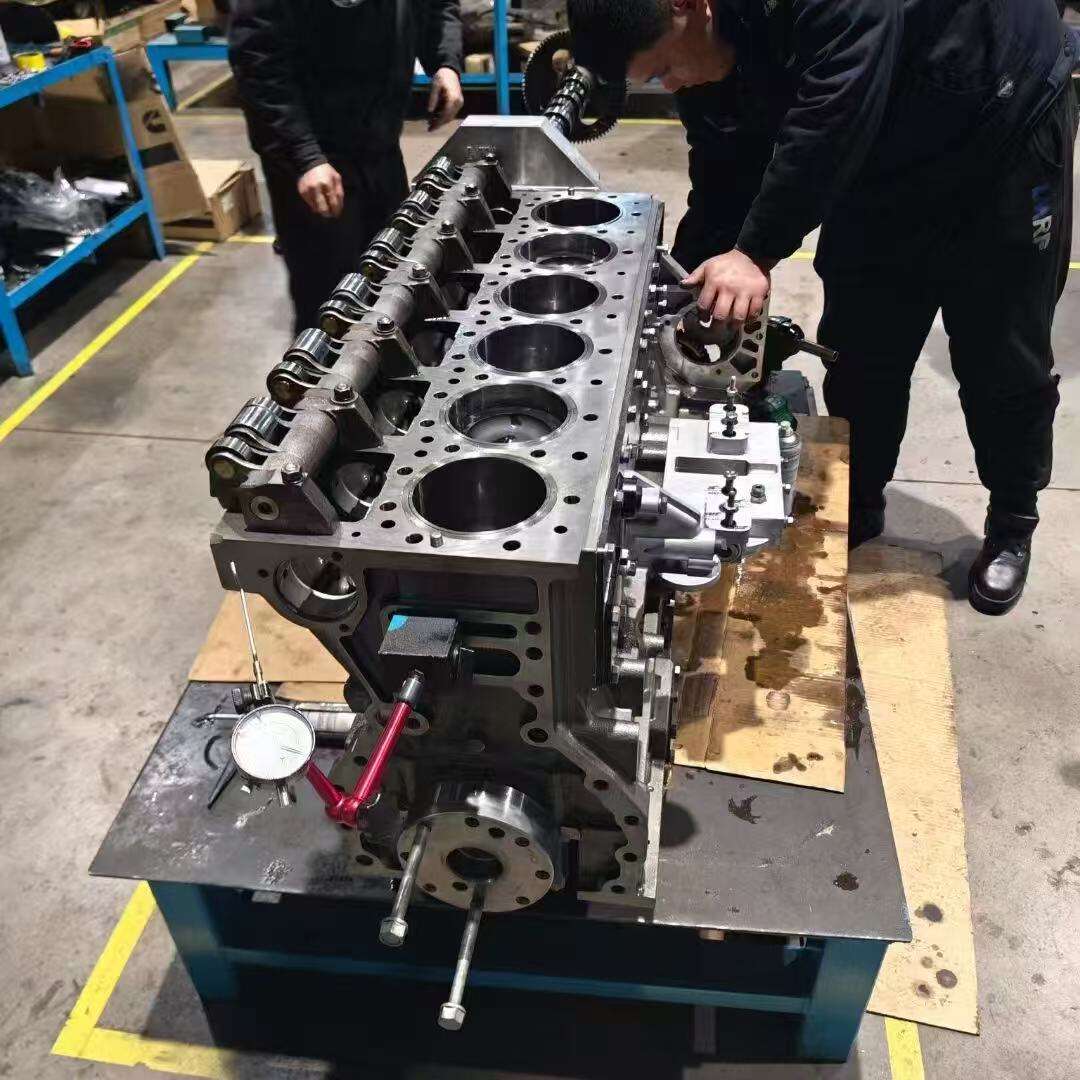

advanced remanufactured engine

Advanced remanufactured engines represent a pinnacle of automotive engineering that combines sustainability with peak performance. These engines undergo a meticulous restoration process where they are completely disassembled, thoroughly cleaned, and rebuilt to meet or exceed original equipment manufacturer (OEM) specifications. Each component is carefully inspected, with worn parts replaced using state-of-the-art materials and precision engineering techniques. The process incorporates modern technological advancements, including updated valve systems, enhanced combustion chamber designs, and improved oil circulation systems. These engines feature reinforced internal components, precision-machined surfaces, and upgraded bearing materials that contribute to increased durability and performance. The application of advanced remanufactured engines spans across various sectors, from personal vehicles to commercial fleets, offering a cost-effective solution without compromising on quality or reliability. They are particularly valuable in high-performance applications where engine dependability is crucial. The integration of modern electronic control systems ensures optimal fuel efficiency and reduced emissions, making these engines both environmentally responsible and economically sensible.