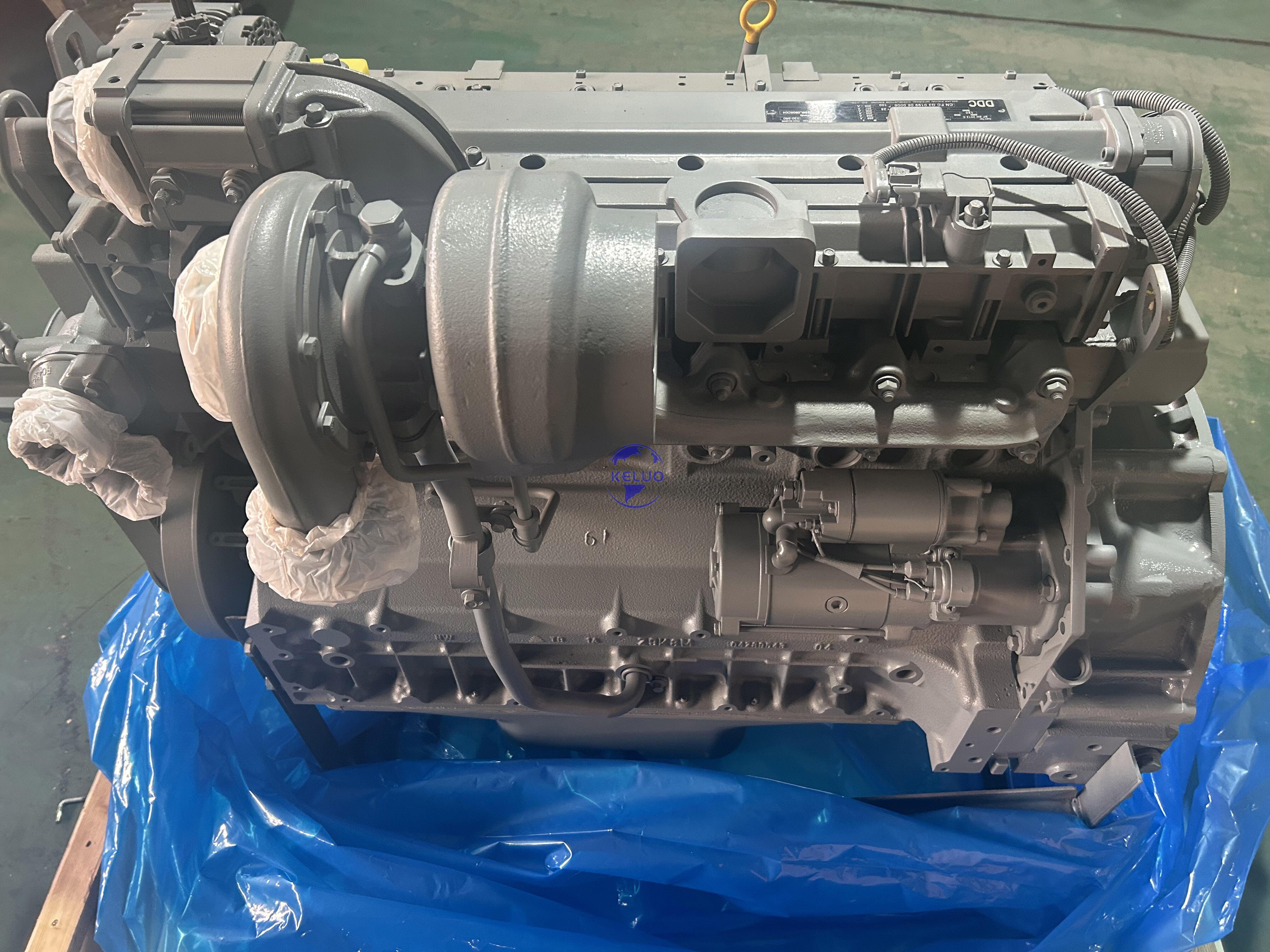

excavator engine made in china

Excavator engines made in China represent a significant advancement in construction machinery manufacturing, combining reliability with cost-effectiveness. These engines are specifically designed to meet the demanding requirements of heavy-duty construction equipment, delivering consistent power output and optimal fuel efficiency. The engines feature advanced combustion technology that ensures complete fuel burning, resulting in reduced emissions while maintaining high performance standards. Typically ranging from 60HP to 500HP, these power units incorporate sophisticated electronic control systems that monitor and adjust engine parameters in real-time. The robust construction includes reinforced cylinder blocks, precision-engineered crankshafts, and high-grade materials that contribute to extended service life. Chinese manufacturers have invested heavily in research and development, implementing modern manufacturing processes that meet international quality standards. These engines are compatible with various hydraulic systems and can be integrated into different excavator models, offering versatility in application. The cooling systems are designed to handle extreme working conditions, featuring efficient heat dissipation mechanisms that prevent overheating during prolonged operation. Additionally, these engines come equipped with advanced filtration systems that protect internal components from contamination, ensuring reliable performance in dusty construction environments.