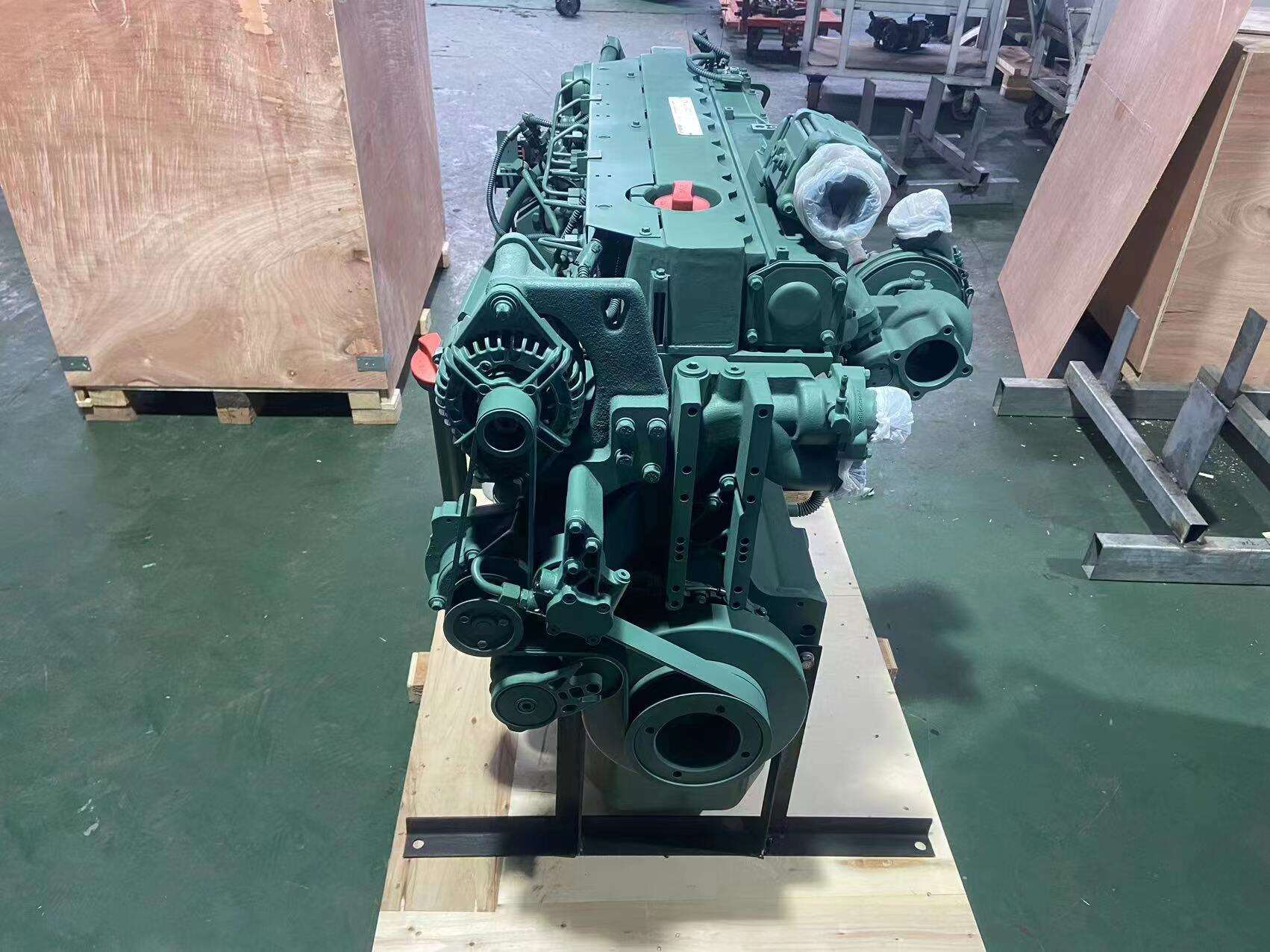

quality loader engine

The quality loader engine represents a groundbreaking advancement in material handling technology, combining robust performance with intelligent automation. This sophisticated system utilizes advanced sensors and precision controls to optimize loading operations across various industrial applications. The engine features a state of the art monitoring system that continuously evaluates load distribution, speed, and efficiency metrics in real time. At its core, the quality loader engine incorporates adaptive learning algorithms that optimize loading patterns based on material characteristics and environmental conditions. The system's modular design allows for seamless integration with existing infrastructure, while its reinforced framework ensures durability under demanding conditions. Notable features include automatic load balancing, predictive maintenance alerts, and energy efficient operation modes. The engine's versatility makes it suitable for multiple industries, including manufacturing, warehousing, and logistics. With its advanced safety protocols and emergency override systems, the quality loader engine maintains operational integrity while protecting both personnel and materials. The system's intuitive interface enables operators to monitor and adjust parameters with minimal training, enhancing workplace productivity and reducing operational downtime.