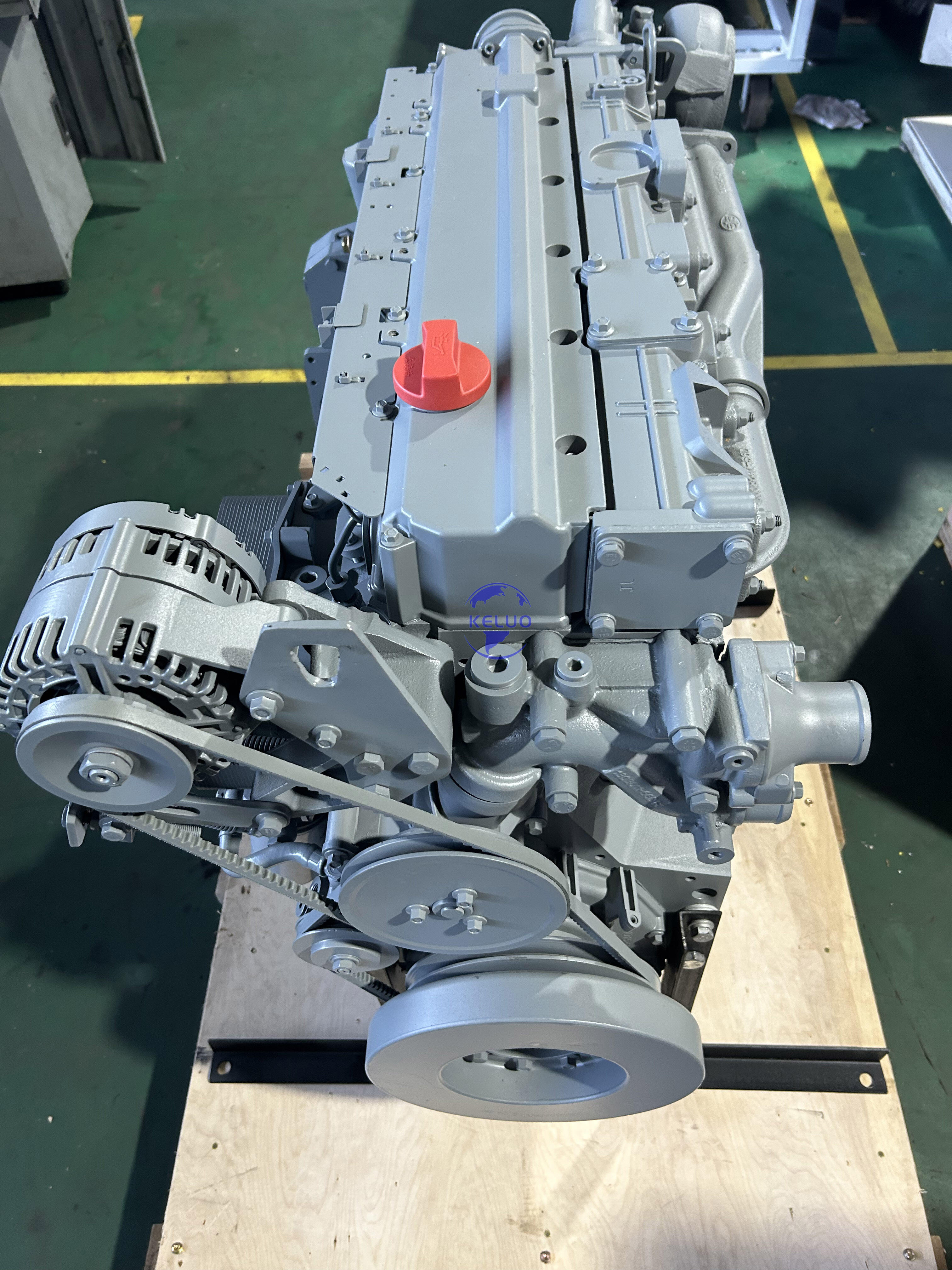

low price excavator engine

The low price excavator engine represents a cost-effective solution for construction and earthmoving equipment, delivering reliable performance without compromising on essential features. This engine system incorporates advanced fuel injection technology and optimized combustion chambers to ensure efficient operation while maintaining affordability. Built with durability in mind, these engines typically range from 50 to 200 horsepower, making them suitable for various excavator sizes and applications. The design emphasizes simplified maintenance requirements, featuring easily accessible service points and commonly available replacement parts. These engines comply with basic emission standards while providing sufficient torque for demanding excavation tasks. The cooling system is engineered to maintain optimal operating temperatures even under heavy workloads, incorporating robust radiators and efficient coolant circulation. Key components are manufactured using quality materials that balance cost and longevity, ensuring a reasonable service life despite the competitive price point. The engine control unit (ECU) manages essential functions while keeping the electronic architecture straightforward, reducing both initial costs and potential maintenance expenses. This makes it an ideal choice for contractors and construction companies looking to maximize their equipment investment without sacrificing fundamental performance capabilities.