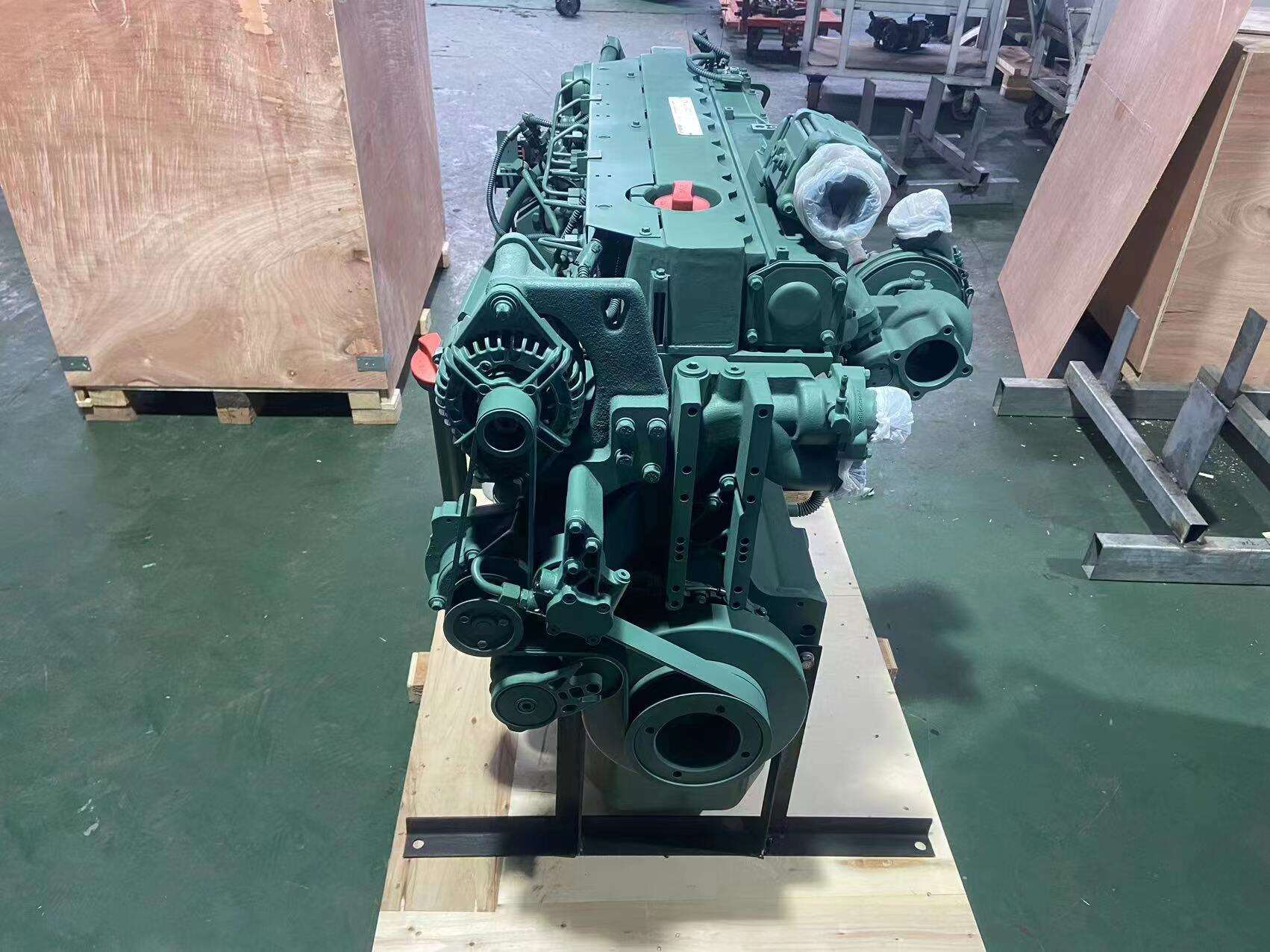

loader engine made in china

The loader engine made in China represents a significant advancement in construction and industrial machinery technology. These engines are engineered to deliver reliable performance while maintaining cost-effectiveness. Featuring advanced fuel injection systems and optimized combustion chambers, these engines provide exceptional power output ranging from 50 to 300 horsepower, depending on the model. The engines incorporate modern emission control technologies to meet international environmental standards while maintaining fuel efficiency. Chinese manufacturers have invested heavily in research and development, resulting in engines that feature sophisticated electronic control units (ECUs) for precise operation and monitoring. These engines are designed with durability in mind, utilizing high-grade materials and robust construction techniques that ensure extended service life under challenging conditions. The cooling systems are enhanced to maintain optimal operating temperatures even in extreme environments, while the advanced filtration systems protect critical components from contamination. These engines are compatible with various loader configurations and can be integrated into different machinery setups, making them versatile choices for construction companies and industrial operations. The maintenance requirements are streamlined with easily accessible service points and extended service intervals, reducing downtime and operating costs.