buy excavator engine

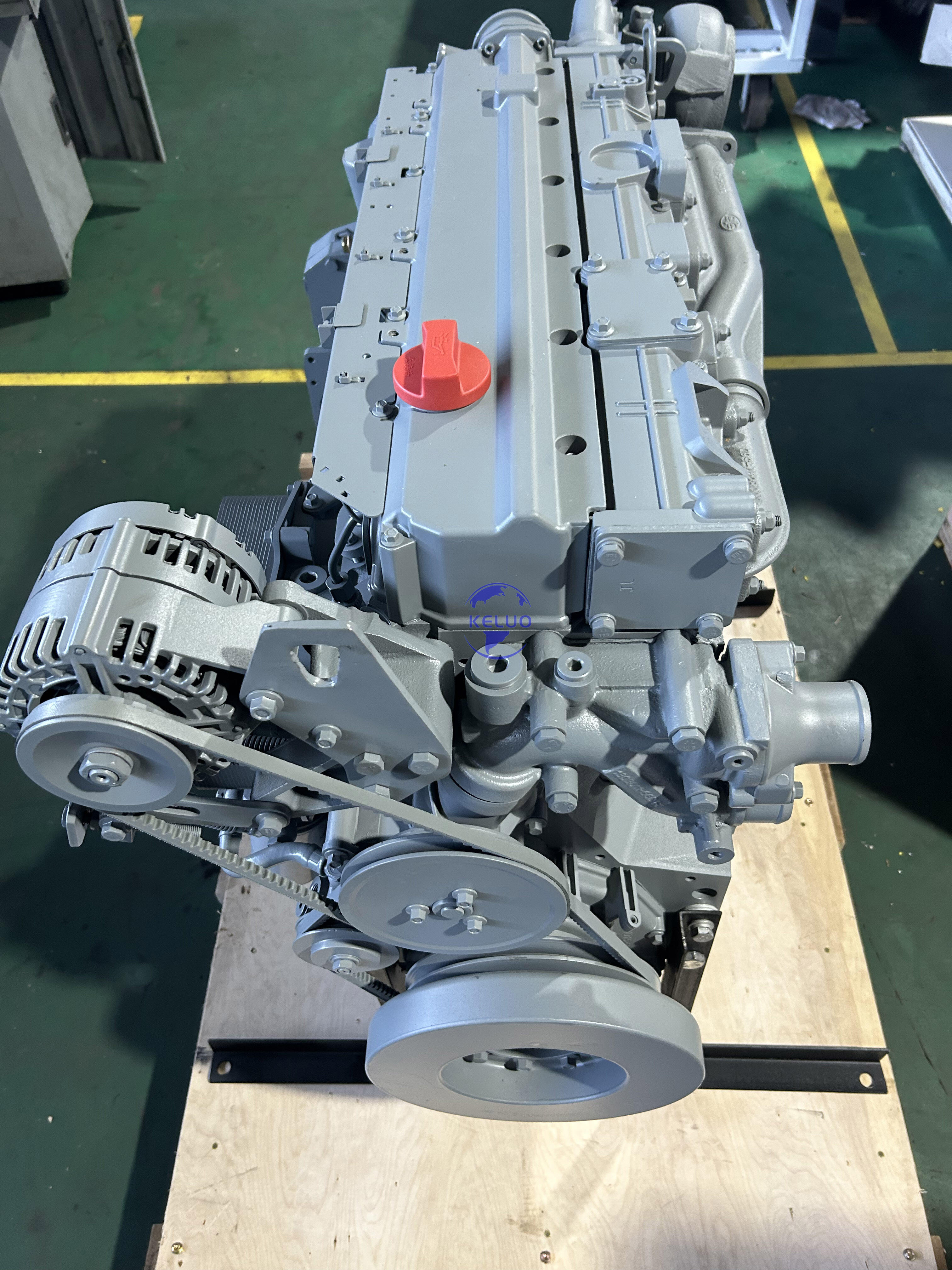

The excavator engine represents a crucial investment for construction and mining operations, combining robust performance with reliability. These powerhouses are engineered to deliver consistent power output while maintaining fuel efficiency across various operating conditions. Modern excavator engines feature advanced electronic control systems that optimize fuel injection timing and monitor engine parameters in real-time. They are designed with heavy-duty components, including reinforced cylinder blocks, hardened crankshafts, and high-grade pistons, ensuring longevity in demanding environments. The cooling system is engineered to maintain optimal operating temperatures even under extreme conditions, while the filtration system effectively removes contaminants to protect internal components. These engines comply with current emission standards through integrated technologies such as selective catalytic reduction and diesel particulate filters. They offer various power ratings to match specific application requirements, from compact urban construction to large-scale mining operations. The modular design facilitates easier maintenance and repairs, reducing downtime and operating costs.