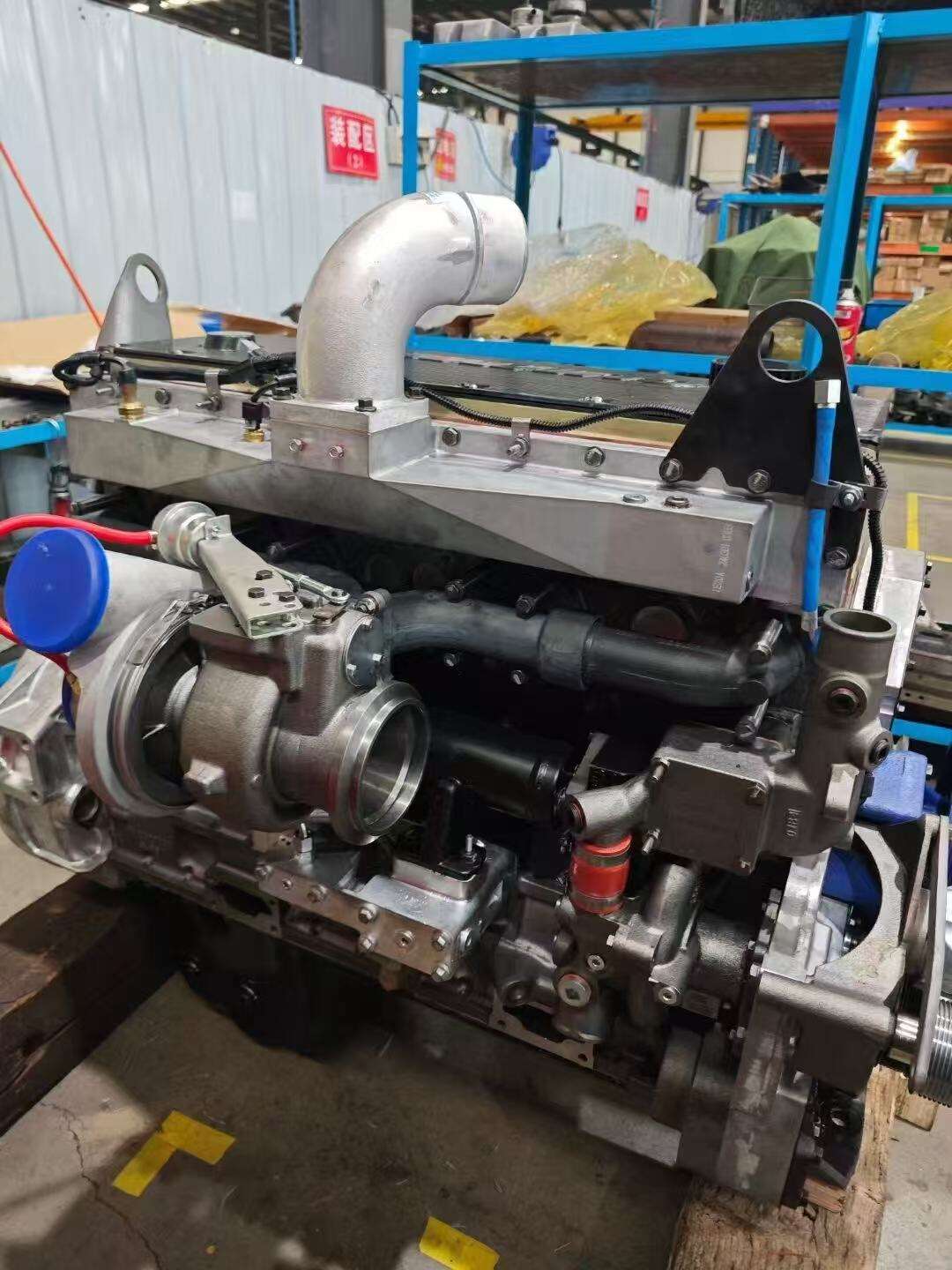

wholesale remanufactured engine

A wholesale remanufactured engine represents a meticulously restored power unit that has been completely disassembled, inspected, and rebuilt to meet or exceed original equipment manufacturer specifications. These engines undergo a comprehensive restoration process that includes replacing worn components with new or reconditioned parts, precision machining of critical surfaces, and extensive testing to ensure optimal performance. The remanufacturing process involves thorough cleaning of all components, detailed inspection for wear patterns, and replacement of critical parts such as pistons, rings, bearings, and timing components. Advanced quality control measures are implemented throughout the rebuilding process, including computerized testing of tolerances and sophisticated diagnostic procedures. These engines are particularly valuable for fleet operators, automotive repair facilities, and vehicle manufacturers seeking cost-effective, reliable replacement solutions. The process incorporates the latest technological advancements in engine rebuilding, utilizing state-of-the-art equipment for precision machining and assembly. Each engine undergoes rigorous performance testing on specialized dynamometers to verify power output, efficiency, and reliability before distribution. This ensures that every wholesale remanufactured engine meets strict quality standards and provides dependable service comparable to new engines.